Why is OEM Manufacturing Important for Hydrogel Cooling Patches?

In recent years, hydrogel cooling patches have emerged as a must-have wellness product across the globe. Whether used for fever relief, migraine management, or post-workout recovery, their convenience, skin-friendliness, and instant cooling effect make them a top choice for both consumers and healthcare providers. As market demand grows, more brands are looking to enter this niche. However, launching a successful hydrogel cooling patch product requires more than just a good idea—it requires the right manufacturing approach.

This is where OEM manufacturing comes into play. Partnering with a reliable hydrogel cooling patches Manufacturer or hydrogel cooling patches Supplier through OEM solutions can be the difference between a struggling product and a best-selling brand. In this article, we will explore why hydrogel cooling patches OEM manufacturing is crucial, how it enables custom hydrogel cooling patches and private label hydrogel cooling patches success, and what businesses should consider when selecting an OEM partner.

1. Understanding OEM Manufacturing for Hydrogel Cooling Patches

OEM (Original Equipment Manufacturer) manufacturing means a brand works with a third-party manufacturer to produce products under the brand’s name. In the case of hydrogel cooling patches, the OEM partner handles the production, quality control, and sometimes even packaging, while the brand focuses on marketing, distribution, and customer engagement.

For example, if you want to launch your own private label hydrogel cooling patches, you can work with a hydrogel cooling patches OEM provider to produce the patches according to your formula preferences, packaging design, and branding requirements.

Key Advantages of OEM Manufacturing:

Scalability – Rapidly increase production without building your own factory.

Customization – Tailor size, shape, ingredients, and packaging for custom hydrogel cooling patches.

Compliance – Leverage the manufacturer’s certifications and testing processes.

Cost-Effectiveness – Avoid the capital investment of setting up production facilities.

2. Why OEM Manufacturing is Crucial for Hydrogel Cooling Patches

2.1 Faster Time-to-Market

In the competitive wellness and healthcare industry, speed matters. Working with a hydrogel cooling patches Manufacturer that offers OEM services allows you to:

Skip the lengthy R&D setup phase.

Use proven formulas and production lines.

Launch your brand faster than competitors.

For instance, if there’s a sudden spike in demand for children’s cooling patches during flu season, an OEM partner can help you meet the demand quickly.

2.2 Access to Advanced Technology

Hydrogel cooling patches OEM providers often invest heavily in modern manufacturing technologies, such as:

Precision gel-mixing equipment.

Automated cutting and sealing machines.

Skin-friendly adhesive innovations.

This means your brand benefits from high-performance cooling patches without needing to develop these capabilities in-house.

2.3 Consistent Product Quality

Reputation in the health and wellness market depends heavily on consistency. A trusted hydrogel cooling patches Supplier ensures every batch meets the same high standards. OEM partners follow strict quality control protocols, often with:

GMP (Good Manufacturing Practice) certification.

ISO quality management systems.

Skin irritation and safety testing.

This protects your brand from complaints or recalls.

2.4 Brand Differentiation Through Customization

Customization is where OEM truly shines. Custom hydrogel cooling patches can include:

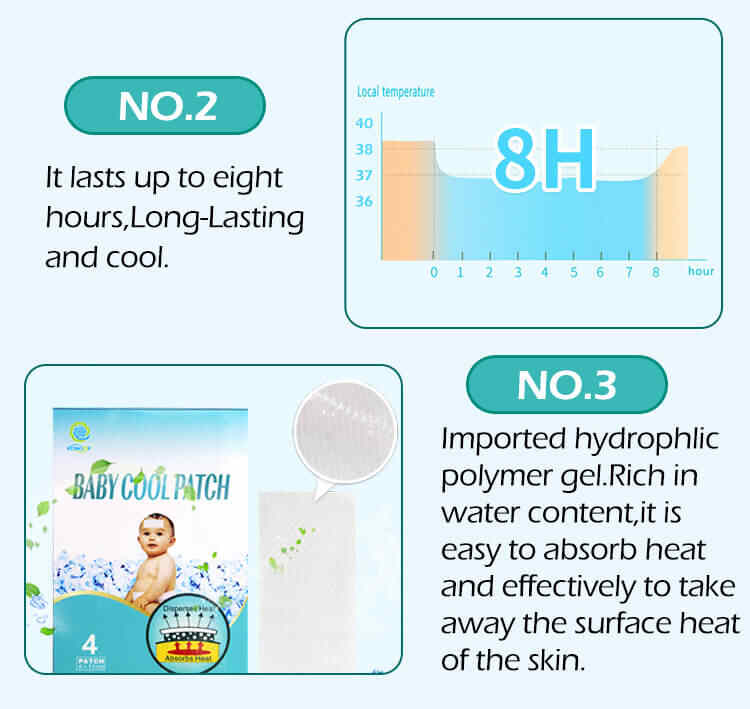

Different cooling durations (4 hours, 8 hours, 12 hours).

Varied patch sizes for adults or children.

Added herbal extracts for extra soothing effects.

Special packaging for premium markets.

A strong hydrogel cooling patches OEM partner can turn these ideas into tangible products that stand out on store shelves.

2.5 Lower Financial Risk

Starting your own manufacturing facility is costly and risky. By partnering with a hydrogel cooling patches Manufacturer, you:

Avoid large capital investments.

Reduce operational risks.

Focus on sales and brand growth rather than production headaches.

3. The Role of Private Labeling in OEM Manufacturing

Private label hydrogel cooling patches allow businesses to sell high-quality products under their own brand without disclosing the original manufacturer. This is common in pharmacy chains, wellness product distributors, and e-commerce brands.

Benefits of Private Labeling:

Control Over Branding – Unique logo, colors, and packaging.

Market Flexibility – Quickly respond to trends without re-engineering production.

Higher Profit Margins – Brand recognition allows for premium pricing.

Customer Loyalty – Consistent quality builds trust.

Many successful e-commerce sellers use private label hydrogel cooling patches OEM production to create recognizable, trusted products without heavy manufacturing investment.

4. How to Choose the Right Hydrogel Cooling Patches OEM Partner

Selecting the right hydrogel cooling patches Supplier is critical. Here are the main factors to evaluate:

4.1 Experience and Reputation

Look for a hydrogel cooling patches Manufacturer with years of OEM experience, positive client testimonials, and a proven track record in healthcare product manufacturing.

4.2 Compliance and Certifications

Ensure your OEM partner meets relevant quality and safety standards:

GMP certification.

ISO 9001 quality management.

Relevant FDA or CE approvals if exporting internationally.

4.3 Customization Capabilities

Ask whether the manufacturer can handle custom hydrogel cooling patches requests such as unique gel formulas, packaging designs, or size variations.

4.4 Production Capacity

Make sure the hydrogel cooling patches Supplier can scale production to meet seasonal or sudden increases in demand.

4.5 Transparent Communication

Choose an OEM partner that provides clear production timelines, cost breakdowns, and regular progress updates.

5. Real-World Example: Scaling a Hydrogel Cooling Patch Brand with OEM

Imagine a mid-sized wellness company wanting to launch a children’s fever relief patch line. They partner with a hydrogel cooling patches OEM that already has:

Skin-safe, hypoallergenic formulas.

Child-friendly packaging designs.

Production facilities capable of producing 500,000 units per month.

Within just three months, the company launches its private label hydrogel cooling patches nationwide, gaining retail placement in major pharmacy chains. Without OEM manufacturing, this would have taken over a year and significantly higher investment.

6. The Future of OEM in the Hydrogel Cooling Patch Market

The hydrogel cooling patches OEM industry is expected to grow due to:

Rising global demand for non-medicated pain and fever relief.

Increased popularity of home healthcare products.

Expanding e-commerce markets.

Innovations in gel formulations, packaging materials, and eco-friendly manufacturing will make OEM partnerships even more valuable in the coming years.

Conclusion

OEM manufacturing is not just an option—it’s a strategic advantage for any brand entering the hydrogel cooling patch market. Partnering with a capable hydrogel cooling patches Manufacturer or hydrogel cooling patches Supplier ensures:

Faster market entry.

High and consistent quality.

Customization opportunities.

Reduced financial and operational risks.

Whether you’re launching custom hydrogel cooling patches for a niche audience or building a mass-market line of private label hydrogel cooling patches, the right hydrogel cooling patches OEM partner can help you dominate the market.

Related Questions & Answers

Q1: What is the difference between OEM and ODM for hydrogel cooling patches?

A1: OEM produces products based on your specifications and branding, while ODM offers pre-designed products you can rebrand.

Q2: Can OEM manufacturers create eco-friendly hydrogel cooling patches?

A2: Yes, many OEMs now offer biodegradable packaging and natural gel formulas to meet sustainability demands.

Q3: How much does it cost to start selling private label hydrogel cooling patches?

A3: Costs vary depending on order quantity, customization level, and packaging, but OEM manufacturing usually requires a lower investment than setting up your own factory.

Q4: How do I ensure my hydrogel cooling patches meet safety standards?

A4: Work with a certified hydrogel cooling patches Manufacturer that conducts safety and stability testing and complies with GMP and ISO standards.

Q5: Can I produce small batches with an OEM partner?

A5: Some hydrogel cooling patches Suppliers offer low minimum order quantities for startups, though larger runs are usually more cost-efficient.