Why Is Long-Term Cooperation Important with a Baby Cooling Fever Patches Manufacturer?

In the highly regulated and trust-driven baby healthcare market, choosing a Baby Cooling Fever Patches Manufacturer is only the first step. The real competitive advantage lies in building long-term cooperation with the right Baby Cooling Fever Patches Supplier. For brand owners, distributors, and healthcare companies, sustained partnerships with a professional Baby Cooling Fever Patches OEM directly influence product safety, market access, innovation speed, and brand credibility.

As global demand for Custom Baby Cooling Fever Patches and Private Label Baby Cooling Fever Patches continues to rise, long-term manufacturer relationships have become a strategic necessity rather than an operational convenience.

This article explains why long-term cooperation matters, how it reduces risk, and how it strengthens your brand’s position in the global baby care market.

1. Baby Products Require Consistency, Not Short-Term Transactions

Consistency Is Critical in Baby Healthcare Products

Baby cooling fever patches are applied directly to infants’ skin. Parents expect:

Stable cooling performance

Gentle, non-irritating materials

Reliable adhesive quality

Consistent safety across batches

A long-term partnership with a trusted Baby Cooling Fever Patches Manufacturer ensures consistent formulations, raw materials, and production processes. Short-term suppliers often change materials or processes to reduce costs, increasing quality risks.

By working long term with a reliable Baby Cooling Fever Patches Supplier, brands protect product consistency and consumer trust.

2. Long-Term Cooperation Strengthens Regulatory Compliance

Regulatory Knowledge Builds Over Time

Baby cooling fever patches are subject to different regulatory frameworks across markets. An experienced Baby Cooling Fever Patches OEM develops deep regulatory knowledge over years of cooperation, including:

FDA compliance experience

CE marking support

ISO 13485 quality management systems

Local registration assistance for emerging markets

Long-term cooperation allows the Baby Cooling Fever Patches Manufacturer to:

Maintain stable documentation

Prepare audit-ready records

Anticipate regulatory updates

Reduce registration delays

Switching suppliers frequently increases compliance risks and slows market expansion.

3. Better Customization Through Long-Term Collaboration

Customization Improves with Product Familiarity

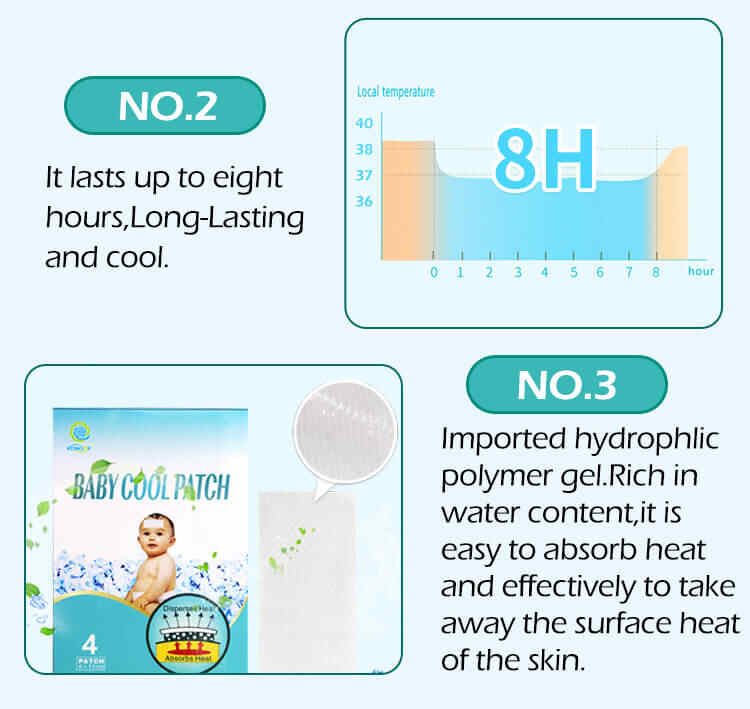

Developing Custom Baby Cooling Fever Patches is not a one-time process. Cooling duration, gel composition, patch size, and adhesive performance often require ongoing optimization.

With long-term cooperation, a Baby Cooling Fever Patches OEM:

Understands your brand positioning

Remembers historical formulation adjustments

Improves product performance iteration by iteration

Shortens R&D cycles

This continuous improvement is almost impossible with transactional, short-term suppliers.

4. Private Label Success Depends on Stable Manufacturing Partners

Why Stability Matters for Private Label Brands

Private Label Baby Cooling Fever Patches rely heavily on manufacturer expertise. A long-term Baby Cooling Fever Patches Supplier helps brands:

Maintain consistent packaging standards

Align product claims with regulations

Control quality across different SKUs

Scale production without quality loss

Private label brands that frequently change manufacturers often struggle with inconsistent appearance, performance variations, and consumer complaints.

Long-term cooperation builds the foundation for strong private label credibility.

5. Improved Quality Control and Traceability

Quality Systems Mature Over Time

An experienced Baby Cooling Fever Patches Manufacturer establishes robust quality systems, but these systems perform best when aligned with specific client requirements.

Long-term cooperation enables:

Customized quality control checkpoints

Client-specific inspection standards

Batch traceability familiarity

Faster root cause analysis

When quality issues arise, long-term partners resolve them more efficiently because they understand your product history in detail.

6. Supply Chain Stability and Risk Reduction

Supply Disruptions Are Brand Killers

The baby healthcare market is highly sensitive to supply interruptions. A long-term Baby Cooling Fever Patches Supplier:

Prioritizes loyal partners during raw material shortages

Maintains safety stock for key clients

Plans production capacity in advance

Reduces lead time fluctuations

Brands with short-term or price-driven supplier relationships are often the first to face delays during market disruptions.

7. Cost Efficiency Beyond Unit Price

Long-Term Cooperation Lowers Hidden Costs

While short-term suppliers may offer lower prices, long-term cooperation with a professional Baby Cooling Fever Patches OEM delivers greater overall value:

Reduced development costs

Lower defect rates

Fewer regulatory errors

Decreased rework and recalls

Over time, stable cooperation significantly reduces total cost of ownership, protecting both margins and brand reputation.

8. Faster Time-to-Market for New Products

Speed Comes from Experience

A long-term Baby Cooling Fever Patches Manufacturer already understands:

Your brand guidelines

Target market regulations

Packaging preferences

Quality expectations

This familiarity enables:

Faster sample development

Shorter approval cycles

Efficient mass production

Quicker response to market trends

Speed is critical in competitive baby care markets, and long-term cooperation creates that advantage.

9. Stronger Communication and Mutual Trust

Trust Is Built, Not Purchased

Long-term cooperation fosters:

Transparent communication

Honest feedback

Proactive problem-solving

Confidentiality protection

A trusted Baby Cooling Fever Patches Supplier is more likely to:

Alert you to regulatory risks

Suggest product improvements

Protect your intellectual property

Support your long-term business goals

Transactional relationships rarely reach this level of strategic collaboration.

10. Long-Term Partnerships Support Sustainable Brand Growth

Manufacturers Grow with Your Brand

As your sales increase, your Baby Cooling Fever Patches Manufacturer must scale production while maintaining quality.

Long-term cooperation allows:

Production capacity planning

Investment in dedicated production lines

Custom tooling development

Strategic cost optimization

Manufacturers are more willing to invest in long-term partners than in short-term buyers.

Conclusion: Long-Term Cooperation Is a Strategic Advantage

In the baby healthcare industry, long-term cooperation with a reliable Baby Cooling Fever Patches Manufacturer is not optional—it is essential.

By working consistently with an experienced Baby Cooling Fever Patches OEM and Baby Cooling Fever Patches Supplier, brands gain:

Product consistency and safety

Strong regulatory compliance

Superior customization capabilities

Private label stability

Supply chain resilience

Sustainable cost efficiency

Long-term cooperation transforms a manufacturer into a strategic partner—one that supports your brand’s growth, reputation, and global expansion.

Frequently Asked Questions (FAQs)

1. Why is long-term cooperation important with a Baby Cooling Fever Patches Manufacturer?

It ensures consistent quality, regulatory compliance, stable supply, and continuous product improvement.

2. Does long-term cooperation improve Custom Baby Cooling Fever Patches development?

Yes. Familiarity with your brand and product history allows faster optimization and better customization results.

3. Is long-term cooperation necessary for Private Label Baby Cooling Fever Patches?

Absolutely. Private label success depends on stable quality, packaging consistency, and manufacturing reliability.

4. How does long-term cooperation reduce business risk?

It minimizes compliance errors, supply disruptions, quality issues, and unexpected cost increases.

5. Can long-term cooperation lower costs even if unit prices are higher?

Yes. Long-term cooperation reduces hidden costs such as rework, delays, regulatory issues, and recalls.

6. How do I start building long-term cooperation with a Baby Cooling Fever Patches Supplier?

Begin with clear expectations, transparent communication, sample testing, and gradual scaling based on performance.