Why Is Certification So Important When Choosing a Medical Cooling Gel Patch OEM?

As global demand for cooling therapy products continues to rise, brands are increasingly turning to professional Medical Cooling Gel Patch OEM partners for product development and manufacturing. Whether you intend to launch a Custom Medical Cooling Gel Patch, expand with a Private Label Medical Cooling Gel Patch, or diversify your portfolio through a reliable Medical Cooling Gel Patch Supplier, one factor matters more than anything else: certification.

In the medical and healthcare sectors, certification is not merely a label—it is evidence of product safety, regulatory compliance, manufacturing integrity, and brand credibility. Choosing a certified Medical Cooling Gel Patch Manufacturer can determine whether your product enters global markets smoothly or faces regulatory obstacles, distribution barriers, and customer mistrust.

This article provides a deep, structured discussion on why certification is essential, how it affects market access, what certifications your OEM must hold, and how brands can leverage certified manufacturing to build trust and long-term success.

1. Certification Defines Trust in the Medical Cooling Gel Patch Industry

Cooling gel patches—commonly used for fever relief, body cooling, headache relief, sports recovery, and post-operative care—are considered regulated medical or healthcare products in many regions. For this reason, trust is a core element of market acceptance.

A certified Medical Cooling Gel Patch Manufacturer demonstrates:

• Proven safety and quality

Certification ensures that raw materials, gel formulations, and patch adhesives are non-toxic, skin-friendly, and clinically safe.

• Compliance with international standards

Authorities require strict documentation and quality systems to protect end users while preventing unsafe products from entering the market.

• Consistency of production

A certified factory follows standardized procedures to maintain stability and performance across every batch.

• Higher acceptance in global distribution channels

Pharmacies, wholesalers, online retailers, and medical suppliers strongly prefer certified products and certified factories.

In short, without certification, it is nearly impossible for a Medical Cooling Gel Patch OEM to support large-scale, global market expansion.

2. Certifications Ensure Regulatory Compliance in Global Markets

Different regions enforce strict regulatory frameworks for medical products. Certification becomes your passport to global trade.

Key examples include:

✔ FDA (U.S. Food & Drug Administration)

Cooling gel patches may be classified as medical devices, especially in pediatric fever care or post-operative use. FDA compliance is often mandatory for entering the U.S. market.

✔ CE Mark (European Union)

Indicates conformity with EU health, safety, and environmental protection standards. Essential for selling in 30+ European countries.

✔ ISO 13485 Certification

The gold standard for medical device quality management systems.

A Medical Cooling Gel Patch Supplier with ISO 13485 certification ensures:

Documented production processes

Traceability of materials

Risk management

Continuous quality improvement

✔ GMP (Good Manufacturing Practice)

Guarantees cleanrooms, hygienic environments, and standardized practices for consistent production.

These certifications are not optional—they are essential for brands targeting global healthcare markets.

3. Certification Protects Your Brand from Legal and Financial Risks

Selecting a non-certified Medical Cooling Gel Patch OEM exposes your business to severe risks:

• Product recalls

Uncertified production may create inconsistencies, leading to health risks and costly recalls.

• Customs rejection

Shipments can be detained or destroyed if documents fail to meet regulatory requirements.

• Legal penalties

Selling non-compliant medical products can result in lawsuits, fines, and market bans.

• Damage to brand reputation

One negative incident can permanently harm trust among consumers and distributors.

Working with a certified Medical Cooling Gel Patch Manufacturer eliminates these threats by ensuring all procedures—from raw materials to packaging—meet global compliance standards.

4. Certification Guarantees High-Quality Materials and Safe Formulations

Medical cooling gel patches involve direct skin contact, making ingredient safety crucial. Certified manufacturers follow strict protocols to ensure:

✔ Hypoallergenic gel formulas

Suitable even for children and sensitive skin users.

✔ Non-toxic adhesives

Maintain strong adhesion without causing irritation.

✔ Cleanroom production

Prevents contamination during manufacturing.

✔ Biocompatibility testing

Ensures the product is safe for prolonged use.

✔ Stability and performance verification

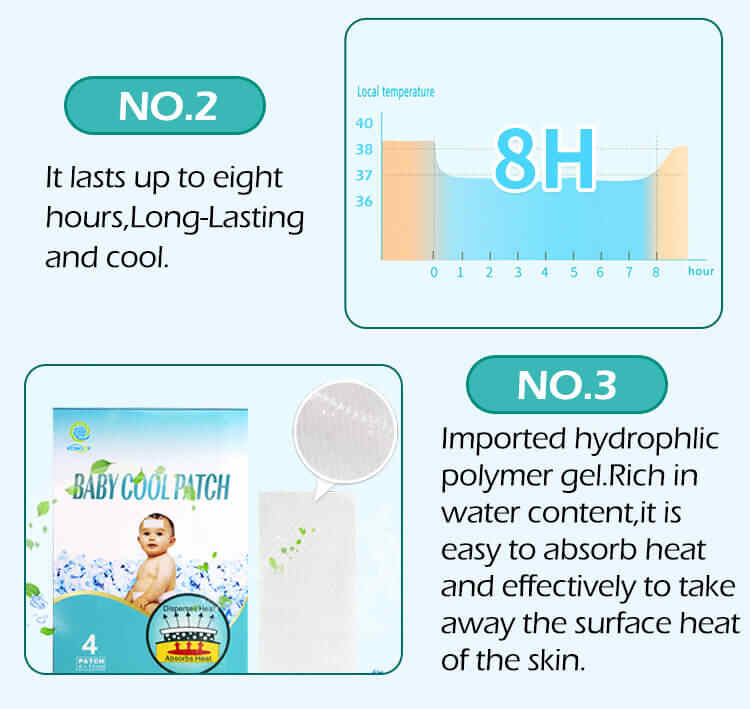

Certified OEMs test for cooling duration, gel consistency, and moisture retention to guarantee product performance.

For brands launching Custom Medical Cooling Gel Patch solutions, certified OEMs have the expertise and systems to support safe and innovative formulations.

5. Why Certification Matters for Private Label Medical Cooling Gel Patch Brands

A Private Label Medical Cooling Gel Patch relies heavily on the manufacturer’s credibility, because:

1. Your brand inherits the OEM’s quality standards

Any defect or contamination traceable to the factory will directly harm your brand reputation.

2. Certified manufacturing enables premium pricing

Consumers trust certified healthcare products and are willing to pay more.

3. Retailers require documentation

Pharmacy chains, hospitals, and distributors will not accept uncertified medical products.

4. Certification protects your marketing claims

Any claims about safety, performance, or child-friendly usage must be backed by testing and certification.

5. Certification supports international expansion

A certified factory makes it easier to register your private label products in new markets.

In essence, certification is not only a compliance requirement—it is a business advantage.

6. Certifications Support R&D and Innovation for Custom Medical Cooling Gel Patch Solutions

Developing innovative cooling gel patch products requires strong quality management. Certified OEMs can offer:

• Advanced R&D laboratories

Ensuring safety, efficacy, and consistency in Custom Medical Cooling Gel Patch formulas.

• Ingredient documentation

MSDS sheets, COA, and allergen reports validate safety claims.

• Controlled formulation adjustments

Certified processes allow quick but safe formula optimization.

• Performance testing equipment

Measuring cooling duration, adhesion performance, and residual gel quality.

• Traceable production batches

Essential for regulatory submissions and export approvals.

Brands benefit from innovation without compromising compliance or safety.

7. Certification Improves Long-Term Supply Chain Stability

A reliable Medical Cooling Gel Patch Supplier must demonstrate predictable and stable production. Certification supports:

• Standardized operations

Reducing production errors, delays, and waste.

• Consistent raw material quality

Certified OEMs only work with approved suppliers.

• Better risk control

Audits and documentation ensure full traceability.

• Easier scaling for global distribution

Certifications reflect a factory’s ability to handle large-volume, stable output.

Whether you are launching in Asia, Europe, or North America, certified production ensures uninterrupted supply and high product confidence.

8. What Certifications a Medical Cooling Gel Patch OEM Should Have

When evaluating a Medical Cooling Gel Patch Manufacturer, look for:

1. ISO 13485

Ensures medical device-level quality management.

2. GMP Certification

Guarantees hygienic and controlled production environments.

3. CE Certification Support

Enables penetration into European markets.

4. FDA Registration (if applicable)

Required for U.S. distribution.

5. MSDS and COA for all ingredients

Confirms raw material safety.

6. Biocompatibility Testing

Proves patches are safe for skin contact.

7. Stability and Performance Test Reports

Ensures cooling consistency and performance.

A qualified Medical Cooling Gel Patch OEM will readily provide these documents during evaluation.

9. How Certification Enhances Global Market Competitiveness

Certified OEM manufacturing allows brands to confidently expand into new countries and new channels.

Benefits include:

• Stronger buyer confidence

Distributors prefer products backed by documented safety and compliance.

• Faster market approvals

Certification reduces registration time in many countries.

• Better product positioning

“ISO Certified” or “CE Approved Facility” is a powerful selling point.

• Higher repeat purchase rates

Consumers trust clinically tested cooling products.

• Compatibility with insurance or hospital procurement

Some institutional buyers require external certification verification.

Certification is a strategic advantage for any brand aiming for global growth.

Conclusion: Certification Is the Foundation of a Successful Medical Cooling Gel Patch OEM Partnership

In the medical and healthcare industry, success is built on trust, safety, and regulatory compliance. Certification ensures that every Custom Medical Cooling Gel Patch or Private Label Medical Cooling Gel Patch meets the highest international standards.

Choosing a certified Medical Cooling Gel Patch Manufacturer guarantees:

Safe ingredients

Reliable performance

Market-ready documentation

Faster global expansion

Stronger brand reputation

Certification is not simply a requirement—it is a competitive advantage and the key to building a scalable, trustworthy healthcare business.

Related Questions and Short Answers

1. What certifications should a Medical Cooling Gel Patch OEM have?

ISO 13485, GMP, FDA registration, CE compliance support, MSDS, COA, and biocompatibility testing.

2. Why is ISO 13485 important?

It ensures the OEM follows medical-grade quality management systems, improving safety, traceability, and consistency.

3. Can uncertified suppliers affect my product launch?

Yes. Without certification, your product may fail customs checks, face legal issues, or be rejected by retailers.

4. Does certification matter for Private Label Medical Cooling Gel Patch brands?

Absolutely. Certification protects your brand reputation and enables global distribution.

5. How can certification improve Custom Medical Cooling Gel Patch development?

It provides structured testing, documented safety standards, and reliable formulation control.