Why Choose Pain Relief Gel Patches OEM for Cost-Effective Production?

In a highly competitive health and wellness market, cost-efficiency without compromising product quality is critical. For businesses looking to launch or expand their pain relief product line, Pain Relief Gel Patches OEM solutions offer a strategic pathway to affordable, scalable, and high-quality manufacturing.

Whether you're an established brand or a startup, partnering with an experienced Pain Relief Gel Patches Manufacturer allows you to access advanced facilities, proprietary formulations, and flexible Private Label Pain Relief Gel Patches options—all at a fraction of the cost of in-house production. This article dives deep into how OEM production helps you reduce operational expenses, streamline product development, and increase profitability.

1. What is OEM and Why Does It Matter?

OEM stands for Original Equipment Manufacturer. In the context of Pain Relief Gel Patches, OEM manufacturers produce products based on your brand's requirements. You focus on branding, marketing, and distribution—while the Pain Relief Gel Patches Supplier handles everything from formulation to packaging.

Key Benefits of OEM Manufacturing:

No need for capital investment in equipment or facilities

Reduced R&D expenses

Lower labor and raw material costs

Faster time-to-market

Expertise in regulatory compliance and quality assurance

Choosing Pain Relief Gel Patches OEM is particularly attractive for companies aiming to enter the market quickly and affordably while maintaining high standards.

2. Reduced Capital Expenditure

Establishing an in-house production facility for Pain Relief Gel Patches involves significant upfront costs—equipment, cleanroom standards, staff training, regulatory certifications, and more. This investment can reach hundreds of thousands of dollars or more.

However, when you partner with a Pain Relief Gel Patches Manufacturer, you eliminate the need for:

Manufacturing equipment

Hiring and training production staff

Maintaining quality control infrastructure

Storage and logistics facilities

This drastically lowers your cost per unit, especially at higher volumes, making OEM an optimal model for cost-effective production.

3. Economies of Scale through Established OEM Infrastructure

A seasoned Pain Relief Gel Patches OEM partner produces large quantities for multiple clients. This allows them to:

Purchase raw materials in bulk at lower prices

Optimize production efficiency

Spread operational costs across product lines

These economies of scale mean lower production costs for you—without compromising product performance or safety. For startups or smaller brands, leveraging this infrastructure provides access to affordable premium products that would be too costly to manufacture independently.

4. Faster Time to Market

Speed matters in today’s fast-paced marketplace. OEM production accelerates the process by eliminating setup time. Many Pain Relief Gel Patches Manufacturers offer:

Ready-to-use formulations

In-house R&D for Custom Pain Relief Gel Patches

Packaging templates

Pre-approved ingredients

This means your product can move from concept to shelf in as little as 4–12 weeks, depending on customization and compliance needs. Faster launch means faster revenue and quicker ROI.

5. Flexible Customization for Market Fit

One of the most compelling features of working with an OEM Pain Relief Gel Patches Supplier is the ability to create Custom Pain Relief Gel Patches without the heavy costs usually associated with formulation development.

You can customize:

Active ingredients (menthol, camphor, lidocaine, CBD, herbal extracts)

Patch size, shape, and adhesion level

Scent (aromatherapy)

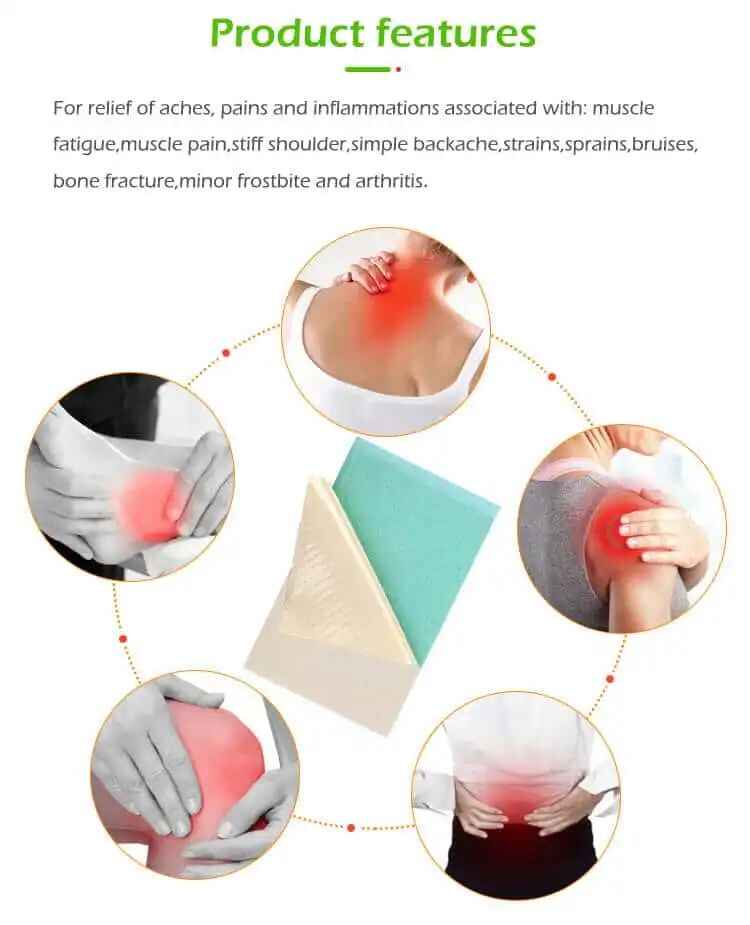

Target usage (muscle, joint, back, neck, etc.)

Packaging design and labeling

This flexibility allows you to cater to niche markets like athletes, seniors, or eco-conscious consumers—enhancing sales potential while keeping development costs low.

6. Private Label Options to Boost Brand Equity

OEM partners commonly offer Private Label Pain Relief Gel Patches services, enabling you to:

Sell ready-made, high-quality products under your brand name

Customize packaging and design

Build brand loyalty with minimal upfront investment

Private labeling not only saves on product development costs but also enhances your brand’s credibility and presence in the market. The faster your product gains traction, the sooner you can scale and expand.

7. Streamlined Compliance and Quality Assurance

Compliance with international regulations (e.g., FDA, CE, ISO, GMP) requires time, expertise, and capital. With a reputable Pain Relief Gel Patches Manufacturer, you benefit from:

Established quality control systems

Pre-validated ingredients

Batch testing and traceability

Up-to-date regulatory documentation

This reduces both the risk of product recalls and the cost of compliance-related delays, while giving customers peace of mind that your product is safe and effective.

8. Cost-Saving Logistics and Packaging Support

Many Pain Relief Gel Patches OEM partners offer end-to-end solutions including:

Bulk and retail-ready packaging

Custom label printing

Storage and inventory management

Global shipping and logistics

By bundling these services, you reduce the need to work with multiple vendors—saving time, money, and the potential for miscommunication or errors.

9. Lower Marketing and Launch Costs

OEM manufacturers often have market-tested formulas, which means you don’t have to spend heavily on trial-and-error R&D. You can use their:

Product performance data

Consumer feedback

Existing certifications

This allows your marketing team to confidently promote the product from day one, reducing promotional risk and improving ROI.

10. Real-World Example (Hypothetical Case)

A mid-sized wellness brand, NatureEase, wanted to launch a herbal Pain Relief Gel Patch line targeting seniors. They collaborated with a certified Pain Relief Gel Patches OEM in Korea that offered Private Label Pain Relief Gel Patches using ginseng and turmeric extracts.

By avoiding in-house production, they saved over $500,000 in startup costs. The OEM also helped them navigate EU compliance. Within 8 months, the brand broke even and was distributing to 14 countries. Their market share in the pain relief segment grew by 35% in just one year.

11. What to Look for in a Pain Relief Gel Patches OEM Partner

Cost-effective production doesn't mean cutting corners. Choose a Pain Relief Gel Patches Supplier that offers:

✅ GMP and ISO-certified facilities

✅ Transparent cost breakdowns

✅ Low minimum order quantities (MOQs)

✅ Customization options

✅ Regulatory support

✅ Packaging and logistics services

✅ Positive client reviews and case studies

Request samples, tour the facility (virtually or in-person), and ensure clear communication before signing any agreement.

Conclusion: A Smart Move for Cost-Conscious Growth

Choosing Pain Relief Gel Patches OEM production is more than a budget decision—it’s a strategic move that enables brands to scale faster, enter the market with confidence, and maintain high product quality while keeping costs under control.

Whether you're looking to offer Custom Pain Relief Gel Patches for niche demographics or launch a full-scale Private Label Pain Relief Gel Patches line, an experienced Pain Relief Gel Patches Manufacturer can help you reach your goals affordably and efficiently.

Cost-effective production doesn’t mean compromising—it means optimizing. Partner with a reliable OEM, and turn your vision into a profitable, market-ready product.

Related Questions and Answers

Q1: Is OEM manufacturing cheaper than in-house production?

A: Yes. OEM eliminates the need for equipment, facilities, and large staffing costs—making it far more affordable, especially for small and mid-sized businesses.

Q2: Can I customize ingredients in Pain Relief Gel Patches with OEM partners?

A: Absolutely. Reputable OEMs offer Custom Pain Relief Gel Patches using various active ingredients and delivery technologies.

Q3: What are Private Label Pain Relief Gel Patches?

A: These are pre-formulated patches produced by an OEM and sold under your brand name, allowing quick market entry and lower development costs.

Q4: How do I ensure my OEM partner is reliable?

A: Verify their certifications (GMP, ISO), request samples, check references, and ensure transparent communication about costs and timelines.

Q5: Are there minimum order quantities (MOQs) with Pain Relief Gel Patches OEM suppliers?

A: Yes, but many suppliers offer low MOQs, especially for first-time clients or private label programs.

Q6: How quickly can I launch a product using OEM production?

A: Depending on customization and compliance, products can be ready in 4 to 12 weeks.