What is the Main Advantage of Working with a Hydrogel Cooling Patches OEM Manufacturer?

In the rapidly expanding health, wellness, and personal care market, hydrogel cooling patches have become a high-demand product. Used for fever relief, headache comfort, sports recovery, and skincare, these versatile patches cater to a diverse range of consumers.

For businesses entering or expanding in this sector, one strategic question often arises: Should we produce in-house or partner with a professional manufacturer? The answer for many successful brands is to work with a hydrogel cooling patches OEM manufacturer.

The main advantage lies in leveraging established expertise and infrastructure to quickly bring high-quality, market-ready products to consumers—without the steep costs and risks of building your own production operation. In this article, we will explore why OEM partnerships are so effective, the broader benefits they provide, and how they empower businesses to scale efficiently.

1. Understanding Hydrogel Cooling Patches and the OEM Model

1.1 What Are Hydrogel Cooling Patches?

Hydrogel cooling patches are adhesive sheets made with a water-rich gel that delivers cooling relief for hours without refrigeration. Their uses include:

Fever and headache management

Muscle soreness relief after exercise

Cooling and soothing sensitive skin

Reducing puffiness in beauty care

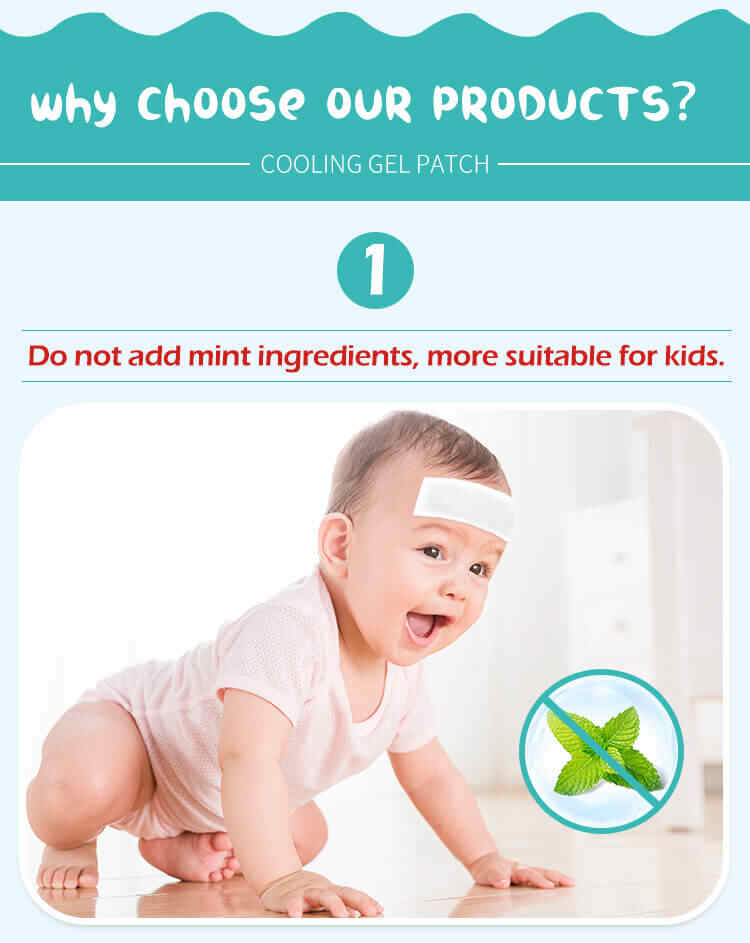

Their drug-free, skin-friendly, and easy-to-use design makes them appealing to consumers of all ages.

1.2 What Does OEM Mean?

OEM stands for Original Equipment Manufacturer. In the context of hydrogel cooling patches OEM, this means you work with a hydrogel cooling patches Manufacturer to produce products under your own brand name.

The OEM partner:

Handles formulation and production

Maintains quality control and compliance

Provides packaging and labeling services

Ships finished goods to your location or customers

This allows you to focus on marketing, distribution, and customer service.

2. The Main Advantage: Expertise and Efficiency

The core benefit of working with a hydrogel cooling patches OEM manufacturer is instant access to professional expertise, advanced facilities, and established processes—without the huge capital investment or time commitment required to build them yourself.

Why this matters:

Faster time-to-market: Instead of spending 12–18 months on product development, you can launch in weeks or months.

Lower upfront costs: No need to buy manufacturing equipment, lease factory space, or hire specialized technicians.

Consistent quality: OEM partners have proven methods and stringent quality checks, reducing the risk of defective products.

Scalable production: Easily adjust production volumes to meet seasonal demand or new market opportunities.

3. Secondary Benefits That Strengthen Your Business

While expertise and efficiency are the main advantage, OEM manufacturing offers several other powerful benefits.

3.1 Product Customization Without the R&D Burden

A good hydrogel cooling patches Supplier can create Custom hydrogel cooling patches tailored to your market:

Sizes and shapes for specific body areas

Formulations with herbal extracts, menthol, or vitamins

Adhesion strength for sports or sensitive skin

Branding elements like unique packaging design

3.2 Compliance and Certification

An experienced hydrogel cooling patches Manufacturer understands global regulatory requirements such as ISO 13485, GMP, CE, or FDA. They can produce goods that meet compliance standards for multiple markets, easing international expansion.

3.3 Private Label Opportunities

With Private Label hydrogel cooling patches, you can brand pre-developed, proven formulations as your own. This eliminates lengthy development cycles and allows for rapid market entry.

3.4 Supply Chain Reliability

Many OEM partners have well-established supplier networks and logistics channels, ensuring consistent availability of raw materials and timely delivery of finished products.

4. How OEM Collaboration Works Step-by-Step

Working with a hydrogel cooling patches OEM manufacturer typically follows this process:

Initial Consultation – Define your product vision, target audience, and budget.

Sample Development – Receive prototypes to test cooling duration, adhesion, and overall feel.

Customization – Adjust size, formulation, scent, and packaging to match your brand identity.

Certification and Testing – Ensure compliance with local and international standards.

Mass Production – Your OEM partner manufactures the agreed quantity at scale.

Packaging and Branding – Products are labeled and packaged under your brand.

Delivery – Goods are shipped to your warehouse or directly to your customers.

5. Case Example: Rapid Market Entry Through OEM

A small wellness company wanted to launch a line of Custom hydrogel cooling patches for athletes. By partnering with an OEM hydrogel cooling patches Supplier:

They developed a high-adhesion, menthol-infused patch for post-training recovery.

The entire process—from concept to retail launch—took only 90 days.

Sales exceeded projections within the first three months due to product quality and targeted marketing.

This success would have been nearly impossible without leveraging the OEM’s existing expertise and facilities.

6. Cost Comparison: In-House vs. OEM

| Factor | In-House Manufacturing | Hydrogel Cooling Patches OEM |

|---|---|---|

| Setup Costs | High (machinery, facility, staff) | Low (OEM already equipped) |

| Time to Market | 12–18 months | 1–4 months |

| Quality Control | Requires building QA systems | Established QA protocols |

| Flexibility | Limited by internal capacity | Scalable with OEM partner |

| Compliance | Need in-house regulatory team | OEM already certified |

7. How to Choose the Right Hydrogel Cooling Patches Manufacturer

To fully benefit from OEM collaboration, you must select a trustworthy partner.

Key factors:

Experience: Years in the industry and a proven track record.

Product Range: Ability to produce multiple types of Custom hydrogel cooling patches.

Certifications: ISO, GMP, CE, FDA.

Scalability: Can handle both small test orders and large bulk production.

Communication: Transparent and responsive throughout the process.

8. Maximizing the Advantage: Tips for Success

Clearly Define Your Needs: Be specific about size, cooling time, packaging style, and target customer.

Order Samples First: Test performance before committing to bulk orders.

Plan for Demand Spikes: Work with your hydrogel cooling patches Supplier to forecast seasonal demand.

Leverage Private Label for Speed: Use Private Label hydrogel cooling patches to enter the market quickly while developing custom options in parallel.

Build a Long-Term Relationship: A strong OEM partnership grows more valuable over time as trust and mutual understanding deepen.

9. Conclusion

The main advantage of working with a hydrogel cooling patches OEM manufacturer is the ability to tap into professional expertise, advanced production capabilities, and proven processes—enabling you to launch high-quality products faster, with less risk and lower cost.

Whether you’re developing Custom hydrogel cooling patches for niche markets or expanding your brand through Private Label hydrogel cooling patches, an experienced hydrogel cooling patches Supplier can be the strategic partner that turns your product ideas into market successes.

In the fast-moving wellness industry, speed and quality are critical. OEM partnerships give you both, positioning your business for sustainable growth.

Related Questions and Short Answers

Q1: What does OEM mean in hydrogel cooling patches manufacturing?

A1: OEM means Original Equipment Manufacturer—your products are produced by a manufacturer but sold under your own brand.

Q2: What is the main advantage of OEM manufacturing?

A2: Faster time-to-market with high-quality products, without the cost and complexity of building your own production facilities.

Q3: Can I create Custom hydrogel cooling patches through an OEM?

A3: Yes, many OEM partners offer full customization in formulation, size, packaging, and branding.

Q4: How do Private Label hydrogel cooling patches work?

A4: They are pre-developed products branded with your label, allowing for quick and low-cost market entry.

Q5: How do I choose the right hydrogel cooling patches Supplier?

A5: Look for experience, certifications, scalability, and a strong reputation for quality and reliability.