Top Innovations in Waist Heat Patch OEM Manufacturing for 2025

The global demand for heat therapy solutions continues to rise as consumers seek convenient and effective products for lower back pain, muscle tension, sports recovery, menstrual discomfort, and daily wellness routines. As a result, the Waist Heat Patch industry has entered a new stage of rapid innovation. In 2025, technological advancements, sustainable materials, and improved manufacturing processes are transforming how products are designed and produced.

For brands aiming to stay ahead of competitors, partnering with a forward-thinking Waist Heat Patches Manufacturer that leads in innovation is no longer optional—it is an essential strategy. This article explores the top innovations shaping Waist Heat Patches OEM manufacturing in 2025, and how these breakthroughs enable brands to create superior Custom Waist Heat Patches and successful Private Label Waist Heat Patches lines.

1. The Evolving Market Landscape of Waist Heat Patches in 2025

Heat therapy remains one of the most trusted remedies for chronic and temporary back pain. With lifestyle changes, longer screen-time, and increasing cases of sedentary work, consumers across the world—especially in the US, Europe, and Asia—are looking for convenient heating solutions.

In 2025, market growth is driven by several trends:

A shift toward natural and drug-free pain relief

Higher awareness of musculoskeletal health

Rising demand for ergonomic and wearable wellness products

Increased e-commerce penetration

Personalization and customization of pain-relief products

These trends push manufacturers to adopt innovations that can deliver more effective, comfortable, and safe heat therapy. A modern Waist Heat Patches Supplier must therefore integrate new technologies, new materials, and intelligent production processes to meet global standards.

2. Innovation #1: Smart Temperature Control Technologies

One of the biggest advancements in 2025 is the integration of precision heating mechanisms in waist heat patches.

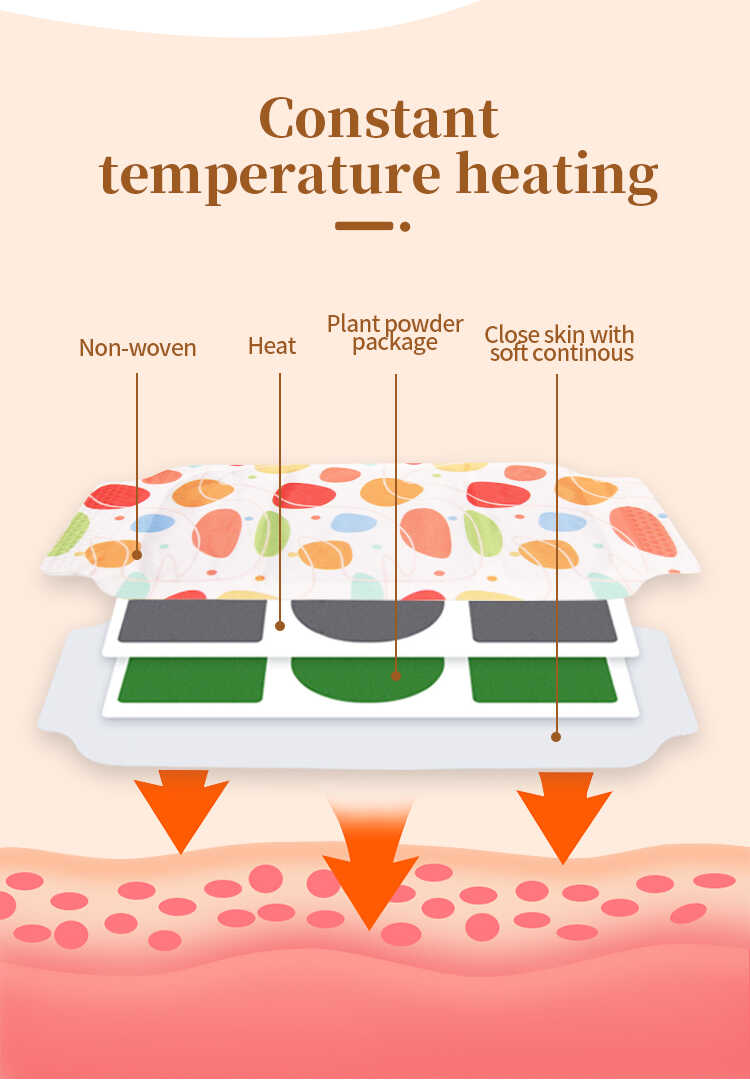

2.1 Stable and Uniform Heat Distribution

Modern Waist Heat Patches OEM facilities use improved heat-generating formulas that ensure:

A consistent temperature throughout wearing

No sudden overheating

Longer and smoother heat release curves

Uniform heat distribution is essential for lower back therapy, where the target area is large and deep.

2.2 Intelligent Self-Regulating Mechanisms

New formulations include self-regulating mechanisms that prevent the patch from exceeding safe temperature limits. This enhances skin safety and reduces the risk of irritation or burns.

2.3 Adjustable Heat Levels

Some advanced Custom Waist Heat Patches now allow brands to offer different heat levels—mild, moderate, and strong—meeting the needs of various consumer groups.

This innovation significantly elevates the user experience and improves brand loyalty.

3. Innovation #2: Longer Heat Duration Performance

Consumers today want products that last longer and remain comfortable throughout the day. In 2025, a standard waist heat patch can provide:

8 hours of stable heat (basic formula)

10–12 hours of long-lasting heat (premium formula)

This is made possible by improvements in:

Iron powder composition

Oxygen permeability layers

Moisture-activation membranes

Heat-stable adhesive structures

A modern Waist Heat Patches Manufacturer invests heavily in formula development to provide these long-duration products, giving brands a strong competitive edge.

4. Innovation #3: Eco-Friendly and Sustainable Materials

Sustainability became a global priority by 2025, and OEM manufacturers are responding.

4.1 Biodegradable and Recyclable Outer Materials

Eco-friendly surface fabrics made from:

Bamboo fiber

PLA (polylactic acid) materials

Recycled polyester

Plant-based nonwoven fabrics

These options help brands position their Private Label Waist Heat Patches as environmentally responsible products.

4.2 Cleaner Heat-Generating Ingredients

The industry is shifting toward:

Natural iron powders

Non-toxic catalysts

Reduced carbon packaging materials

Environmentally conscious innovations allow brands to attract eco-focused consumers and comply with stricter environmental regulations.

5. Innovation #4: Skin-Friendly, Medical-Grade Adhesives

Adherence is essential for waist patches, which must remain firmly attached even during movement.

In 2025, OEM manufacturers have developed new adhesive technologies:

5.1 Hypoallergenic Adhesives

Suitable for sensitive skin, reducing redness and irritation.

5.2 Improved Breathability

Multi-layer breathable structures reduce sweating and increase wearing comfort.

5.3 Wearable Comfort Technology

Thin, soft, and flexible adhesives offer a second-skin feel, especially beneficial for all-day use.

Such upgrades help Waist Heat Patches OEM partners deliver products that consumers trust.

6. Innovation #5: Ergonomically Enhanced Patch Designs

Ergonomic designs have become a core differentiator in 2025.

6.1 3D Contoured Waist Fit

Patches are designed to match the natural curves of the lower back, preventing folding or peeling.

6.2 Stretchable Material Structures

Elastic nonwoven materials allow free movement without losing adhesion.

6.3 Lightweight and Discreet Designs

Thinner patches allow users to wear them discreetly under clothing.

Brands seeking advanced Custom Waist Heat Patches can now offer ergonomically superior products that increase daily comfort and promote better pain relief.

7. Innovation #6: Advanced Manufacturing Automation

Automation is a major driver behind efficiency and consistency in 2025.

7.1 High-Precision Filling Equipment

Automated heat-generating mixture filling ensures:

Exact material weight

Consistent heating results

Zero waste

7.2 Automated Adhesive Layer Application

Ensures perfect alignment and stability.

7.3 Smart Production Monitoring Systems

AI-driven sensors monitor:

Temperature accuracy

Moisture control

Packaging integrity

Automation ensures higher quality and reduces human error—one reason brands choose professional Waist Heat Patches Manufacturer partners.

8. Innovation #7: Customizable Branding and Private Label Solutions

In 2025, more brands want personalized and exclusive products. OEM leaders now offer upgraded services for Private Label Waist Heat Patches.

8.1 Fully Customizable Packaging

Options include:

Minimalist, eco-friendly boxes

Premium printed foil packaging

Custom shapes and patch sizes

High-resolution digital branding

8.2 Exclusive Herbal and Aromatherapy Formulas

Brands can launch signature blends featuring:

Lavender

Ginger

Eucalyptus

Turmeric

Mugwort

These formulations enhance therapeutic benefits and improve user experience.

8.3 Market-Specific Customization

Different markets require different:

Sizes

Heat durations

Materials

Temperature profiles

A flexible Waist Heat Patches Supplier helps brands expand globally with localized product variations.

9. Innovation #8: Clinical Validation and Data-Driven Product Development

Consumers want science-backed wellness products. Therefore, leading OEM manufacturers now integrate clinical testing and data analysis.

9.1 Human Skin Sensitivity Studies

Testing ensures patches are safe for all skin types.

9.2 Thermal Imaging Analysis

Shows how effectively heat penetrates the skin and muscle tissue.

9.3 Real-User Comfort Trials

Provides data for product refinement, enhancing user satisfaction.

This data-driven approach builds trust and improves product performance.

10. Innovation #9: Improved Global Compliance and Export Capabilities

In 2025, compliance is more important than ever.

Top-tier OEM companies now offer:

ISO 9001 and ISO 13485 systems

FDA and CE documentation assistance

MSDS reports

Third-party testing support

Brands can export their Private Label Waist Heat Patches worldwide with confidence.

11. How These Innovations Benefit Brands in 2025

The advancements in OEM manufacturing offer clear benefits:

11.1 Higher Consumer Satisfaction

Better comfort, longer heat duration, and improved safety all drive positive reviews and repeat purchases.

11.2 Stronger Market Differentiation

With unique features, brands can stand out from low-quality competitors.

11.3 Reduced Costs and Faster Production

Automation and improved processes lower operational costs and speed up order fulfillment.

11.4 More Flexible Branding Opportunities

Rich customization options empower brands to build unique identities.

11.5 Better Long-Term Growth Potential

Reliable innovation helps brands scale with confidence and consistency.

Conclusion

The year 2025 represents a breakthrough moment for the heat therapy industry. With innovations in temperature control, sustainability, ergonomic design, adhesive technology, automation, and clinical validation, partnering with a cutting-edge Waist Heat Patches Manufacturer is essential for any brand aiming to lead the market.

Whether you are expanding your product line through Custom Waist Heat Patches, launching your own Private Label Waist Heat Patches, or seeking a dependable Waist Heat Patches Supplier, choosing an OEM partner that prioritizes innovation will directly impact your brand’s success.

OEM manufacturing is no longer just about production—it is about technological partnership, market competitiveness, and a long-term growth strategy.

Related Questions & Short Answers

1. What innovations should I look for when choosing a Waist Heat Patches OEM partner?

Look for advances in heat control, eco-friendly materials, ergonomic design, automation, and clinical validation.

2. How can Custom Waist Heat Patches help my brand?

Customization allows you to create unique formulas, packaging, and temperature profiles that differentiate your brand.

3. Are Private Label Waist Heat Patches suitable for new brands?

Yes, they help startups launch high-quality products quickly with lower R&D and production costs.

4. Why is automation important in heat patch manufacturing?

Automation ensures consistency, safety, efficiency, and faster order completion.

5. How do innovations improve user experience?

They enhance comfort, prolong heat duration, improve adhesion, and ensure better temperature stability.