The Science Behind Hydrogel Cooling Patches: Why OEM Quality Matters

In the competitive healthcare and personal care markets, hydrogel cooling patches have emerged as a trusted solution for fever relief, headache management, sports injury care, and even cosmetic treatments. Their rising popularity means more brands are entering the market — but not all products are created equal. The science behind these patches reveals that OEM quality plays a crucial role in performance, safety, and consumer satisfaction.

By working with an experienced hydrogel cooling patches manufacturer or hydrogel cooling patches OEM supplier, brands can ensure their products deliver proven effectiveness while meeting strict quality standards. This article explores the science of hydrogel cooling technology, why OEM quality matters, and how custom hydrogel cooling patches and private label hydrogel cooling patches can elevate a brand’s market position.

1. Understanding Hydrogel Cooling Patches

Hydrogel cooling patches are soft, water-based sheets designed to deliver cooling relief through a combination of evaporation and heat absorption. The primary components include:

Water – Often 60–90% of the gel matrix, responsible for cooling through evaporation.

Polymer network – Maintains gel structure and adhesion to skin.

Functional additives – Menthol, herbal extracts, or vitamins for added benefits.

Backing material – Prevents moisture loss on one side and provides structural support.

2. The Science of Cooling: How Hydrogel Patches Work

The cooling effect is based on endothermic evaporation. When the water in the gel absorbs body heat, it slowly evaporates, taking heat energy with it and lowering skin temperature.

Additional benefits of hydrogel cooling patches include:

Consistent temperature reduction without the risk of ice burns.

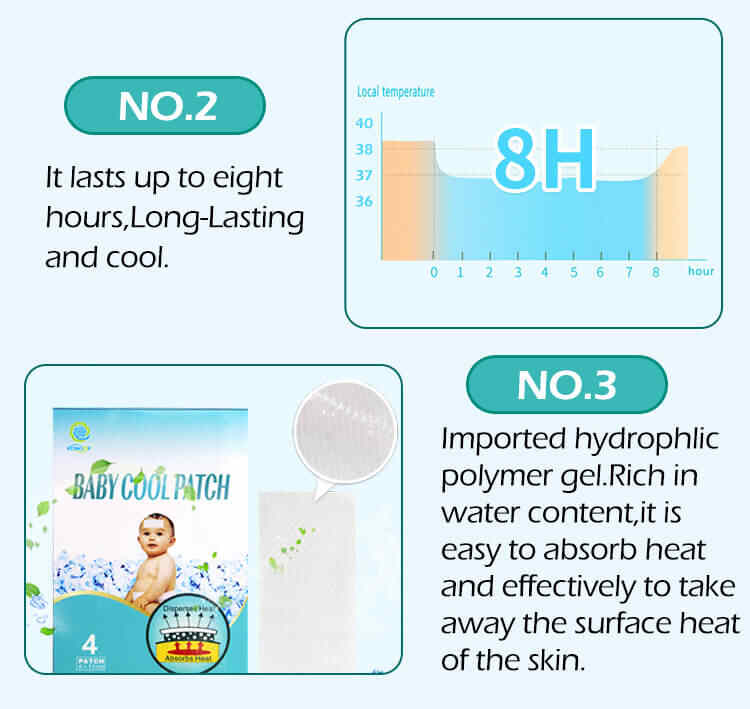

Extended duration — high-quality patches can last 6–8 hours.

Localized relief — only the targeted area is cooled.

The precision of this cooling depends heavily on the formulation, which is why partnering with a reliable hydrogel cooling patches OEM manufacturer is essential.

3. Why OEM Quality Matters

3.1 Formulation Consistency

An established hydrogel cooling patches manufacturer has the technical expertise to ensure every batch maintains the same cooling performance, adhesive strength, and skin compatibility.

3.2 Ingredient Purity

Reputable hydrogel cooling patches suppliers source pharmaceutical-grade polymers, safe preservatives, and high-purity water to minimize skin irritation risks.

3.3 Safety Compliance

OEM factories typically follow ISO, CE, and FDA standards, guaranteeing that both private label hydrogel cooling patches and custom hydrogel cooling patches meet regulatory requirements for safety and efficacy.

3.4 Performance Testing

Leading OEM partners conduct rigorous laboratory testing to measure cooling temperature drop, duration, adhesive integrity, and user comfort.

4. Customization in Hydrogel Cooling Patches OEM

High-quality OEM manufacturing enables brands to tailor their products to market demand. Popular customization options include:

Formula enhancements — Herbal extracts like chamomile, mint, or green tea for natural soothing.

Shape and size variations — Forehead patches, under-eye patches, or large sports injury sheets.

Skin sensitivity options — Hypoallergenic, fragrance-free, or pediatric-specific formulations.

Eco-conscious materials — Biodegradable backings and recyclable packaging.

These custom hydrogel cooling patches help brands differentiate their offerings and target niche audiences effectively.

5. Private Label vs. Fully Custom Production

Private label hydrogel cooling patches offer ready-made solutions branded with your logo and packaging. They’re ideal for quick market entry and low R&D investment.

Custom hydrogel cooling patches involve working closely with the OEM manufacturer to develop a unique product from scratch. This is ideal for brands targeting specific customer needs or unique selling points.

Both approaches benefit from OEM quality assurance — the difference lies in speed to market versus full product uniqueness.

6. Key OEM Quality Factors That Influence Performance

Water Retention Rate – Determines how long the patch maintains cooling.

Polymer Quality – Affects gel stability, flexibility, and adhesion.

Adhesive Strength – Must stick securely without leaving residue or causing irritation.

Microbial Control – OEM-level sterilization ensures the product remains safe throughout its shelf life.

Temperature Drop Curve – Controlled, steady cooling is preferred over sharp, short-lived drops.

7. Scientific Advantages of OEM-Manufactured Hydrogel Cooling Patches

Longer-lasting cooling performance due to optimized gel composition.

Improved skin compatibility from dermatologically tested formulas.

Higher consumer trust due to consistent quality and safe materials.

Global compliance that enables distribution in multiple countries without reformulation.

8. The Role of R&D in OEM Manufacturing

A high-level hydrogel cooling patches OEM facility invests heavily in R&D to:

Explore novel polymers for enhanced moisture retention.

Test natural cooling agents to replace synthetic additives.

Develop heat-sensitive formulations for adaptive cooling.

Optimize packaging films for longer shelf life.

This scientific investment translates into better-performing private label hydrogel cooling patches and custom hydrogel cooling patches.

9. Case Study: OEM Quality in Action

A European wellness brand partnered with a hydrogel cooling patches supplier to develop pediatric cooling patches with animal-themed designs and gentle, fragrance-free gels. OEM expertise ensured:

6+ hours of consistent cooling.

Dermatologist-approved formula safe for sensitive skin.

Fun packaging that boosted retail sales.

The product launched successfully in 14 countries within one year, demonstrating the scalability of OEM-driven innovation.

10. How to Choose the Right Hydrogel Cooling Patches OEM Manufacturer

Look for:

Proven track record with documented case studies.

Certifications (ISO, CE, FDA).

Custom formulation capabilities.

Flexible MOQs for testing new markets.

Strong communication throughout the development process.

Conclusion

The science behind hydrogel cooling patches proves that performance and safety depend on precise formulation, quality materials, and rigorous testing — all of which are hallmarks of a reputable hydrogel cooling patches OEM manufacturer.

Whether you opt for private label hydrogel cooling patches for fast entry or custom hydrogel cooling patches for unique market positioning, OEM quality ensures your brand delivers reliable results, earns consumer trust, and stands out in a crowded marketplace.

Related Questions and Answers

Q1: How do hydrogel cooling patches work?

A1: They absorb body heat and release it through evaporation, lowering skin temperature in a controlled way.

Q2: Why is OEM manufacturing important for hydrogel cooling patches?

A2: OEM ensures consistent quality, safety compliance, and scientifically validated performance.

Q3: Can OEM suppliers create custom formulas?

A3: Yes, they can add natural ingredients, adjust cooling duration, and modify shapes or sizes.

Q4: Are private label hydrogel cooling patches as good as custom ones?

A4: Yes, if produced by a reputable OEM manufacturer — the main difference is speed to market and uniqueness.

Q5: How long can a high-quality hydrogel cooling patch last?

A5: OEM-engineered patches can provide cooling for 6–8 hours depending on formulation.