The Role of Quality Control in Waist Heat Patch OEM: Ensuring Safety and Consistency

In today’s fast-growing wellness and pain-relief market, consumer expectations for safety, comfort, and performance are higher than ever. Brands entering the space for heat therapy solutions—particularly waist heat patches—must rely on a trustworthy Waist Heat Patches Manufacturer that prioritizes quality control at every stage of production. Whether your business focuses on Waist Heat Patches OEM, Custom Waist Heat Patches, or Private Label Waist Heat Patches, a rigorous quality control system is essential to maintaining product reliability, regulatory compliance, and long-term customer loyalty.

This in-depth discussion explores why quality control is the backbone of successful OEM manufacturing, the key QC processes used by leading suppliers, and the standards your business should expect from a professional Waist Heat Patches Supplier.

1. Why Quality Control Is Essential in Waist Heat Patch OEM

Quality control (QC) is not just a technical requirement—it is a strategic advantage. When selecting a Waist Heat Patches Manufacturer, the quality control framework directly influences product safety, brand reputation, and market competitiveness.

1.1 Protecting Consumer Safety

Heat patches produce thermal energy through controlled oxidation. Without strict quality control, dangers include:

Overheating and skin burns

Uneven heat distribution

Chemical leakage

Poor adhesion leading to patch displacement

A trusted OEM maintains strict heat testing and material screening to ensure every product is safe for daily use.

1.2 Guaranteeing Consistency Across Batches

Consumers expect the same level of comfort every time they use your product. Strong QC ensures:

Stable heating curves

Uniform temperature duration

Consistent adhesive strength

Reliable shelf life

This consistency is essential whether you are producing Custom Waist Heat Patches or ready-made private label versions.

1.3 Meeting International Regulatory Standards

High-quality Waist Heat Patches OEM manufacturers follow global compliance standards such as:

ISO 13485 medical device manufacturing

GMP standards

MSDS ingredient documentation

CE / FDA / UKCA support

Strong QC minimizes the risk of customs delays, product recalls, and customer complaints.

1.4 Protecting Your Brand Reputation

A single product failure can affect thousands of users. Consistency and safety protect your credibility—especially when scaling a line of Private Label Waist Heat Patches worldwide.

2. Key Quality Control Processes in Waist Heat Patch Manufacturing

Leading manufacturers implement multi-layered QC systems covering raw materials, production, performance testing, and packaging.

2.1 Raw Material Inspection

Every batch of components used in heat patches must meet strict standards. These include:

High-Grade Heating Formula

Iron powder purity

Activated carbon quality

Moisture control

Salt and mineral proportions

Any deviation can affect heat output and safety.

Medical-Grade Substrates

A reliable Waist Heat Patches Supplier uses materials that are:

Hypoallergenic

Breathable yet durable

Non-irritating to sensitive skin

Adhesive Testing

Adhesives must stay secure even during movement or sweating. QC checks for:

Peel strength

Skin tolerance

Resistance under temperature changes

2.2 In-Process Quality Control During Production

A professional Waist Heat Patches Manufacturer employs automated and manual QC checks at every production stage.

2.2.1 Automated Mixing of Heating Materials

The iron powder mixture must be uniform to ensure stable heat generation. Quality teams verify:

Particle consistency

Moisture content

Proper blending ratios

2.2.2 Patch Formation and Filling Checks

Each heat patch must contain precise filling weights. QC monitors:

Filling machine accuracy

Uniform distribution of the heating mixture

Thickness consistency

2.2.3 Adhesive Layer Application

Incorrect adhesive layers can lead to:

Patch falling off

Skin irritation

Uneven heating sensation

QC ensures exact adhesive thickness and uniform coverage.

2.2.4 Cutting, Sealing, and Shape Verification

Automated cutting machines are inspected regularly for accuracy. QC teams check:

Shape consistency

Seal tightness

Finishing quality

2.3 Heating Performance Testing

This is one of the most crucial aspects of OEM quality control.

2.3.1 Temperature Accuracy Testing

Manufacturers test for:

Warm-up time

Peak temperature

Safety thresholds for skin

Consistency across samples

2.3.2 Heat Duration Verification

Depending on the design, patches may last 6, 8, 10, or 12 hours. QC ensures actual performance matches product claims.

2.3.3 Heat Curve Stability

A reliable Waist Heat Patches OEM supplier provides detailed heat curves showing:

Temperature rises

Plateau phases

Decline curves

These curves reflect the patch’s reliability and safety.

2.4 Adhesion and Flexibility Tests

Heat patches must remain attached to the waist during walking, bending, or working. QC tests include:

Bending resistance

Sweat exposure simulations

Peel force consistency

Long-wear comfort testing

Patches that fall off too easily or irritate skin damage brand trust.

2.5 Packaging Integrity Testing

Packaging plays a major role in preserving product quality.

QC Checks Include:

Airtight sealing

Moisture barrier strength

Durability testing under temperature changes

Shelf life simulations

Leading manufacturers conduct accelerated aging tests to ensure Private Label Waist Heat Patches remain effective for 2–3 years.

3. Compliance and Certifications: The Foundation of Trust

To evaluate a Waist Heat Patches Manufacturer, examining their compliance credentials is essential.

3.1 ISO and GMP Standards

Manufacturers should hold:

ISO 13485: medical device quality management

ISO 9001: general quality system

GMP certification: clean and standardized production

These certifications confirm rigorous oversight and documentation.

3.2 International Testing Reports

A reliable supplier should provide:

Safety data sheets (MSDS)

Biocompatibility testing reports

Heating performance reports

Toxicology evaluations

This documentation helps brands pass import regulations quickly.

3.3 Regulatory Support for Global Markets

OEM partners should support compliance with:

CE and RoHS (EU)

FDA regulations (U.S.)

UKCA

TGA listing (Australia)

This makes global distribution of Custom Waist Heat Patches much smoother.

4. The Role of R&D in Quality Assurance

R&D innovation is crucial for safe and high-performing heat patches.

4.1 Temperature Control Innovations

R&D teams optimize oxidation reactions to:

Prevent overheating

Extend heat duration

Ensure stability across climates

These innovations are especially important for premium OEM products.

4.2 Development of New Formulas and Features

Modern brands often want:

Herbal-infused patches

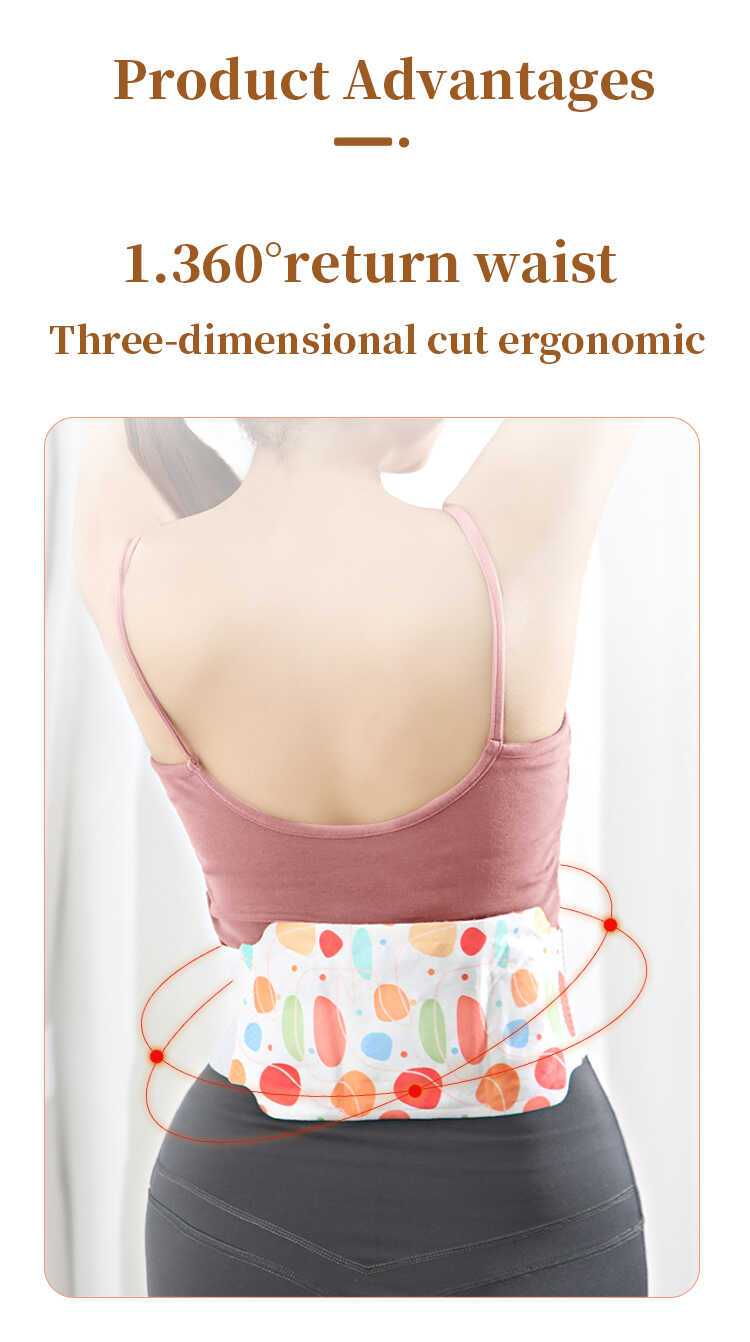

Slim-fit ergonomic designs

Extended heat duration

Eco-friendly packaging

A strong Waist Heat Patches Supplier provides innovation-driven solutions.

4.3 Customization for Brand Differentiation

For brands producing Custom Waist Heat Patches, R&D teams help create:

Unique heating formulas

Custom shapes and sizes

Exclusive fragrance or herbal blends

Enhanced breathability materials

This gives your product a competitive edge.

5. End-of-Line Inspection and Traceability

Before packaging and shipping, each batch undergoes final inspection:

Visual checks for defects

Random testing of heat performance

Adhesive integrity checks

Barcode and traceability labeling

Traceability systems allow manufacturers to track every batch back to raw materials—critical for safety and recall management.

6. How Quality Control Impacts Private Label Waist Heat Patches

For brands choosing Private Label Waist Heat Patches, quality control ensures:

Fast market entry with validated formulas

Lower risk because products are pre-tested

Reliable product performance in all conditions

Consistent customer experience across all markets

Private label products rely heavily on the manufacturer’s QC system—therefore choosing the right partner is vital.

7. What Brands Should Look For in a QC-Driven OEM Partner

To ensure you are selecting a professional, trustworthy Waist Heat Patches OEM partner, evaluate:

Availability of complete QC documentation

Transparency in product testing

Ability to provide heat curve reports

Support for certification and regulatory filing

Strong R&D capabilities

History of exports to major global markets

Clean, automated manufacturing environment

These indicators reflect the manufacturer’s commitment to quality and long-term partnerships.

Conclusion: Quality Control Is the Backbone of a Successful Waist Heat Patch Brand

Quality control is not optional—it is the foundation of every successful heat patch product. A reliable Waist Heat Patches Manufacturer ensures consistent performance, safe heating levels, and compliance with global standards. Whether you choose Custom Waist Heat Patches to build a unique brand identity or launch Private Label Waist Heat Patches for fast market entry, partnering with a QA-focused Waist Heat Patches Supplier guarantees that your products meet the highest standards of safety and reliability.

Brands that prioritize OEM partners with strong QC systems benefit from:

Higher customer satisfaction

Stronger global competitiveness

Reduced regulatory risk

Faster scaling opportunities

Simply put, your brand’s reputation depends on manufacturing quality—and quality starts with control.

Related Questions and Short Answers

1. Why is quality control important in Waist Heat Patches OEM?

It ensures product safety, stable heating performance, consistent quality, and regulatory compliance.

2. What QC tests should a Waist Heat Patches Manufacturer perform?

Heating curve testing, ingredient purity checks, adhesion tests, packaging integrity testing, and shelf-life simulations.

3. What certifications should OEM manufacturers have?

ISO 13485, ISO 9001, GMP, and MSDS, plus CE or FDA support depending on market.

4. How do Custom Waist Heat Patches benefit from strong QC?

Customization requires rigorous testing to ensure new formulas and shapes heat safely and consistently.

5. Are Private Label Waist Heat Patches safe?

Yes—if produced by a compliant manufacturer with strong QC processes and certified materials.