The Role of Quality Control in Menstrual Heating Pad OEM Manufacturing: Protecting Brand Reputation

In the competitive wellness and feminine care market, quality control is not just a production step—it is the foundation of brand trust and long-term success. For brands working with a Menstrual Heating Pad Manufacturer or Menstrual Heating Pad OEM, quality control plays a vital role in ensuring that each product delivered to consumers meets the highest standards of safety, performance, and reliability.

Women rely on menstrual heating pads for comfort and relief during one of the most sensitive times of the month. Any defect, inconsistency, or safety issue can not only harm users but also damage a brand’s reputation beyond repair. This is why every Menstrual Heating Pad Supplier, from those offering Custom Menstrual Heating Pads to Private Label Menstrual Heating Pads, must maintain a strict and transparent quality management system.

This article explores the critical role of quality control in Menstrual Heating Pad OEM manufacturing, outlining how it protects your brand image, ensures compliance, and supports sustainable growth in an increasingly quality-conscious market.

1. Why Quality Control Is the Cornerstone of Menstrual Heating Pad OEM Manufacturing

Quality control ensures that every product that leaves the production line meets defined safety and performance standards. In Menstrual Heating Pad OEM manufacturing, this involves overseeing every stage—from material selection to final packaging.

For brands, partnering with a Menstrual Heating Pad Manufacturer that prioritizes quality means:

Lower risk of product recalls or customer complaints.

Enhanced consumer trust and brand loyalty.

Compliance with global regulations, enabling smoother international sales.

Consistent product performance that strengthens brand reputation.

Ultimately, quality control safeguards your business from reputational damage while ensuring that your menstrual heating pads deliver comfort and safety with every use.

2. Key Stages of Quality Control in Menstrual Heating Pad Production

Quality control in menstrual heating pad manufacturing is a multi-step process designed to detect and correct any potential defect before products reach the market.

2.1. Raw Material Inspection

The foundation of quality begins with sourcing high-grade, safe materials. A reliable Menstrual Heating Pad Supplier inspects all incoming materials, such as:

Heating compounds (iron powder, activated charcoal, salt) for consistency and purity.

Non-woven fabrics and adhesives for hypoallergenic properties and skin safety.

Packaging materials for durability, moisture resistance, and compliance with safety standards.

Only certified materials are used to ensure that the pads are safe, effective, and gentle on the skin.

2.2. In-Process Monitoring

Throughout the manufacturing process, Menstrual Heating Pad Manufacturers conduct strict checks to ensure uniformity and performance stability. Quality engineers monitor parameters such as:

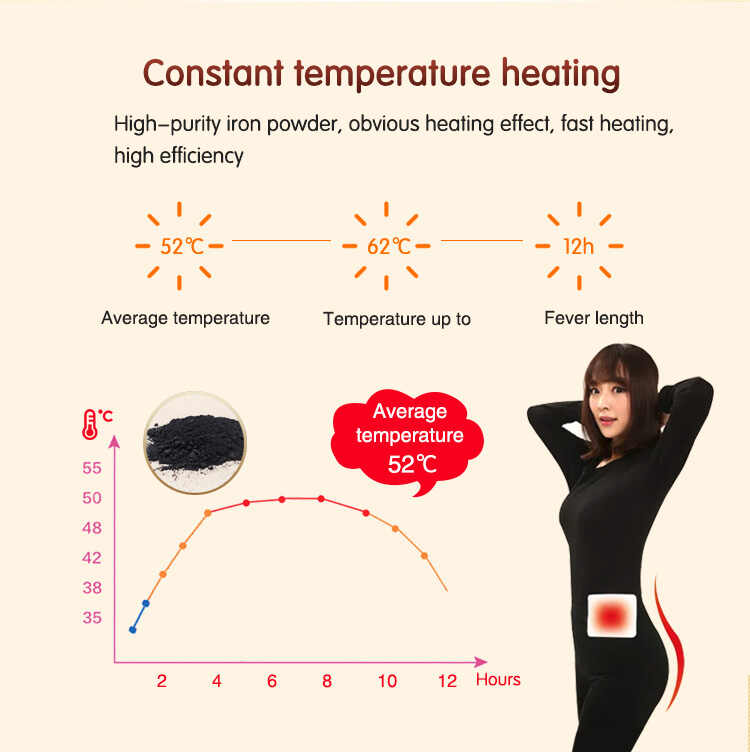

Heating temperature and duration consistency.

Adhesive strength and patch durability.

Moisture and air permeability of outer materials.

This prevents defects like overheating, uneven heating, or adhesive failure that could compromise user experience.

2.3. Finished Product Testing

Before packaging, every Custom Menstrual Heating Pad and Private Label Menstrual Heating Pad undergoes multiple performance tests, including:

Temperature control tests to ensure safe heat levels (typically between 40–60°C).

Safety tests for skin irritation, burn resistance, and toxicity.

Shelf life and stability tests to confirm that the heating effect lasts as promised.

These tests ensure consistency across all product batches and confirm compliance with international safety regulations.

3. The Role of Certification in Quality Assurance

Certifications are formal recognition of a manufacturer’s adherence to strict production and safety standards. Working with a Menstrual Heating Pad OEM that holds international certifications not only ensures product quality but also enhances your brand’s credibility.

3.1. Essential Certifications to Look For

ISO 9001: Demonstrates a robust quality management system.

CE Certification: Confirms product safety for the European market.

FDA Registration: Essential for products entering the U.S. market.

RoHS/REACH Compliance: Guarantees environmentally safe materials.

3.2. Certification as a Trust-Building Tool

Displaying certification logos on product packaging boosts consumer confidence. It signals that your Menstrual Heating Pad Manufacturer upholds globally recognized safety and quality standards—critical in the competitive wellness market.

4. How Quality Control Protects Brand Reputation

Brand reputation is one of the most valuable assets in any business. In the menstrual care industry, trust is everything. Consumers expect not only comfort but also safety and consistency from the brands they use.

4.1. Preventing Product Failures and Recalls

A single batch of defective menstrual heating pads can lead to negative reviews, product recalls, and even legal challenges. Quality control ensures that such incidents are minimized or prevented entirely through rigorous inspection and testing.

4.2. Building Long-Term Customer Loyalty

When customers have a positive experience with your Custom Menstrual Heating Pad or Private Label Menstrual Heating Pad, they are more likely to recommend your brand. Reliable quality translates directly into brand loyalty, repeat purchases, and word-of-mouth growth.

4.3. Strengthening Market Competitiveness

Brands backed by high-quality manufacturing stand out in global markets. A strong quality reputation allows you to expand into new regions with confidence, supported by your Menstrual Heating Pad OEM’s track record of excellence.

5. Advanced Technologies Enhancing Quality Control

Modern Menstrual Heating Pad Manufacturers are adopting advanced technologies to achieve higher precision and reliability in production.

5.1. Automated Production Systems

Automation reduces human error and ensures consistent quality across large-scale production. Automated weighing, sealing, and temperature calibration systems improve both efficiency and accuracy.

5.2. Smart Testing Equipment

Innovative sensors and infrared thermometers help detect inconsistencies in heating elements during production. These systems can identify irregularities long before products reach consumers.

5.3. Data-Driven Quality Tracking

Some advanced Menstrual Heating Pad OEMs use digital tracking systems to record data from each production batch. This enables traceability and quick identification of root causes if a defect arises later.

6. Collaboration Between Brands and OEMs in Quality Management

Maintaining product quality is a shared responsibility between brands and their Menstrual Heating Pad OEM partners. Clear communication, transparent audits, and ongoing collaboration are key to ensuring quality standards remain high.

6.1. Setting Clear Quality Standards

Brands should clearly define product specifications—such as heating duration, temperature tolerance, and material types—before production begins. These standards serve as measurable benchmarks during quality inspections.

6.2. Regular Quality Audits

A proactive Menstrual Heating Pad Supplier welcomes third-party audits and brand inspections. This transparency helps maintain accountability and ensures consistent production practices.

6.3. Feedback Integration

Quality improvement is an ongoing process. Feedback from customers should be communicated to the Menstrual Heating Pad Manufacturer so they can implement improvements in design, materials, or production methods.

7. Quality Control in Custom and Private Label Menstrual Heating Pads

Both Custom Menstrual Heating Pads and Private Label Menstrual Heating Pads require tailored quality assurance strategies to maintain brand consistency and consumer satisfaction.

7.1. For Custom Menstrual Heating Pads

Custom projects involve unique formulas, designs, or packaging. Therefore, OEMs must implement stricter quality protocols to ensure that new concepts meet functional and safety expectations before mass production.

7.2. For Private Label Menstrual Heating Pads

Private label solutions use pre-existing formulations, but quality control ensures that every batch maintains the same high performance as the original sample. Consistency here is key to preserving brand integrity.

8. The Cost of Poor Quality Control

Neglecting quality control has severe consequences:

Product recalls that lead to financial losses.

Damage to brand reputation and consumer trust.

Legal liabilities due to non-compliance or consumer harm.

Loss of competitive edge in international markets.

In contrast, investing in a quality-driven Menstrual Heating Pad OEM results in lower risk, higher profit margins, and stronger brand equity.

9. Selecting a Quality-Focused Menstrual Heating Pad OEM Partner

To ensure your brand’s long-term success, look for these qualities in a potential Menstrual Heating Pad Manufacturer:

Proven experience in OEM/ODM menstrual care production.

Valid international certifications (ISO, CE, FDA).

Advanced production technology and cleanroom facilities.

Transparent testing and documentation processes.

Willingness to accommodate audits and continuous improvement.

A truly reliable Menstrual Heating Pad Supplier will view quality as a shared goal, not just a contractual obligation.

10. Conclusion: Quality Control as the Guardian of Brand Reputation

In the world of menstrual care, your brand’s success depends on one crucial element—trust. That trust is built on consistent, safe, and high-quality products. Partnering with a quality-driven Menstrual Heating Pad OEM ensures that every pad your customers use reflects your brand’s commitment to comfort, safety, and innovation.

Whether you’re producing a Custom Menstrual Heating Pad to differentiate your product line or launching a Private Label Menstrual Heating Pad to enter the market quickly, quality control must remain at the heart of your strategy.

By choosing an experienced and certified Menstrual Heating Pad Manufacturer, you protect not only your product but your brand’s reputation and future growth.

Related Questions and Answers

Q1: Why is quality control important in Menstrual Heating Pad OEM manufacturing?

A1: Quality control ensures safety, performance consistency, and compliance, protecting both consumers and brand reputation from defects or recalls.

Q2: What certifications should a Menstrual Heating Pad Manufacturer have?

A2: ISO 9001, CE certification, FDA registration, and RoHS/REACH compliance are essential indicators of quality and safety.

Q3: How do Custom Menstrual Heating Pads differ in quality control?

A3: Custom pads require additional testing for new materials, designs, and heating formulas to ensure the final product meets all safety standards.

Q4: What are the common quality issues with low-standard menstrual heating pads?

A4: Overheating, poor adhesive performance, inconsistent heat duration, or allergic reactions caused by substandard materials.

Q5: How can I verify the quality of my OEM partner?

A5: Review certifications, request production reports, inspect sample products, and perform factory audits before finalizing any contract.