Quality Control in Headache Cooling Patch OEM Production: The Foundation of Brand Reputation

In a rapidly expanding wellness market where consumers demand fast, safe, and drug-free pain relief solutions, Headache Cooling Patches have become a widely accepted over-the-counter (OTC) product. As competition rises, more brands are partnering with Headache Cooling Patch OEM manufacturers to launch their product lines efficiently and at scale.

However, manufacturing success is not defined by production volume alone. The true determinant of long-term market trust is quality control. A single defect, poorly performing patch, or inconsistency in formulation can undermine years of brand-building efforts. For this reason, any business entering this industry must evaluate how quality is managed at every stage of the OEM production cycle.

This article analyzes why quality control is the backbone of brand reputation, how it affects end-user confidence, and what businesses should look for when selecting a Headache Cooling Patch Manufacturer. Whether you aim to launch a Private Label Headache Cooling Patch quickly, or develop a unique Custom Headache Cooling Patch, understanding quality control processes is essential for strategic success.

1. Why Quality Control Is the Core of OEM Production

For consumer health products, especially those applied directly to the skin, quality is brand credibility. When a patch sticks too weakly, causes irritation, or fails to deliver cooling relief, customers are unlikely to purchase again. Worse, negative user experiences spread rapidly through online reviews, social platforms, and pharmacies.

Quality control in Headache Cooling Patch OEM manufacturing ensures:

✔ consistent cooling performance

✔ safe and skin-friendly ingredients

✔ standardized adhesive strength

✔ reliable gel structure & moisture retention

✔ stable product appearance and shelf life

Reputation in the wellness market is earned through predictable results—patch after patch, box after box. If quality fluctuates, brand trust collapses.

2. Key Quality Control Elements in OEM Cooling Patch Production

To maintain high standards, a Headache Cooling Patch Supplier should follow structured QC procedures across every production phase. Let’s break these into five critical stages:

2.1 Raw Material Procurement & Verification

The quality of the finished patch begins with materials. A responsible manufacturer conducts sourcing and quality authentication for:

hydrogel polymers

cooling agents like menthol or plant extracts

skin-safe adhesives

non-woven or release backing film

moisture-locking components

Suppliers must provide documentation such as MSDS, COA (Certificate of Analysis), and medical safety reports. A top Headache Cooling Patch Manufacturer only selects materials that are:

✔ hypoallergenic

✔ non-irritating

✔ lab-tested

✔ globally compliant

2.2 Formula Consistency & Stability Testing

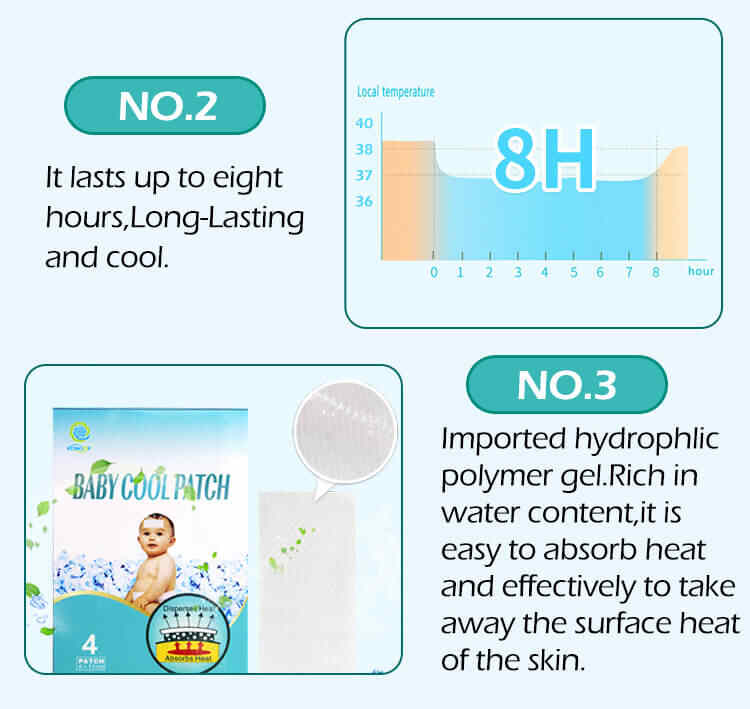

Cooling patches rely on gel composition to deliver soothing effects for 6–12 hours. Therefore, maintaining formula balance is essential.

OEM R&D teams test for:

| Test Category | Purpose |

|---|---|

| Viscosity Stability | Prevent cracking/drying of gel |

| Cooling Duration | Maintain long-lasting refresh sensation |

| Ingredient Distribution | Ensure uniform effect across the patch |

| pH Balance | Prevent skin irritation |

| Sensory Comfort | Improve user experience |

For brands seeking a Custom Headache Cooling Patch, formula precision becomes even more important. A small deviation may alter performance noticeably.

2.3 Production Line Quality Inspection

During manufacturing, automated equipment spreads hydrogel, laminates layers, die-cuts patches, and packages them. A strong Headache Cooling Patch OEM implements real-time monitoring at this stage.

Inspection teams check for:

patch thickness accuracy

air bubble or uneven adhesion

gel saturation uniformity

backing film alignment

surface defects

Advanced factories employ machine-vision systems for defect detection—improving precision and reducing manual error.

2.4 Microbiological & Dermatological Testing

Cooling patches contact skin for long durations, meaning safety validation cannot be overlooked. OEMs should conduct:

✔ biocompatibility tests

✔ dermatology irritation tests

✔ anti-bacterial microbe analysis

These tests protect the user and strengthen brand accountability. They are especially critical for Private Label Headache Cooling Patch production because consumers assume branded products are medically safe—even if the brand does not manufacture them directly.

2.5 Packaging Integrity & Shelf-Life Assurance

Packaging is both protection and branding. A good package maintains gel hydration, prevents contamination, and ensures retail stability across different temperatures.

Quality checks include:

moisture retention analysis

sealing pressure evaluation

transportation simulation

UV and temperature resistance

If packaging fails, even high-quality patches degrade before reaching consumers. Therefore, OEMs must balance aesthetics and protection.

3. How Quality Control Impacts Brand Reputation

A brand’s reputation is not built by marketing—it is built by user experience. Reliable quality ensures that every customer receives the soothing, cooling effect they expect.

Equally, insufficient QC leads to:

❌ non-stick patches reported by customers

❌ allergic reactions causing brand backlash

❌ unstable cooling duration

❌ product recalls and damaged brand image

❌ shrinking retail partnerships and market trust

Quality consistency = customer loyalty.

Customer loyalty = long-term profitability.

4. Why OEM QC Matters More for Private Label Products

Many brands choose Private Label Headache Cooling Patch solutions for quick market entry, but this model comes with higher risk if OEM quality is unstable.

Because the end product carries your brand name—but is produced by the OEM—the manufacturer’s mistakes become your public failure.

Strong QC in OEM ensures:

| Benefit | Brand Outcome |

|---|---|

| Reduced product defect rate | Smaller refund/complaint cost |

| Stable user experience | Higher repurchase rate |

| Reliable lead time | Better retail inventory control |

| Predictable cooling performance | Positive online reputation |

A brand without QC control is at the mercy of public opinion. A brand backed by QC integrity is built to last.

5. QC Requirements for Custom Headache Cooling Patch Projects

Developing a Custom Headache Cooling Patch involves extra QC layers, especially during formula development and prototyping.

A qualified OEM provides:

⭐ extensive R&D formulation support

⭐ multiple sample rounds before mass production

⭐ adjustable cooling strength levels

⭐ safety evaluation for new ingredients

⭐ performance testing under temperature stress

This ensures product uniqueness never compromises safety.

6. How to Evaluate QC Capabilities When Choosing an OEM Supplier

Here is a practical checklist when selecting a Headache Cooling Patch Manufacturer:

| QC Indicator | What to Look For |

|---|---|

| Certifications | ISO 13485, GMP, CE/FDA compliance |

| Material Traceability | Full MSDS, COA reports |

| In-House Lab | Formula testing, stability research |

| Automated Lines | Higher accuracy, lower defect rates |

| Documented QC Process | SOPs for inspection checkpoints |

| Microbiology Testing | Skin & allergen safety ensured |

| Shelf-Life Validation | Packaging + long-duration cooling proof |

The best Headache Cooling Patch Supplier will transparently share data instead of hiding numbers or refusing audits.

7. Relationship Between Quality Control and Market Expansion

Brands supported by strong OEM QC:

✔ gain pharmacy and retail approval more easily

✔ attract medical distributors and global buyers

✔ build product lines with premium pricing

✔ develop customer lifetime value instead of one-time purchases

Quality is not a cost—it is an investment multiplier.

Weak QC does not reduce cost—it creates loss through returns, complaints, and brand collapse.

8. Final Insight: Quality Control Protects & Elevates Brand Value

OEM production is the foundation of most modern wellness brands, but not all OEMs are equal. A patch that cools for eight hours instead of four, adheres smoothly instead of peeling, or feels soothing instead of irritating—that is the difference QC makes.

A strong Headache Cooling Patch OEM not only manufactures products but protects your brand image with every patch released into the market. Quality control supports consumer confidence, drives repeat sales, and ultimately determines whether a brand becomes disposable or indispensable.

In an industry where users want comfort, safety, and fast relief—quality is reputation, and reputation is growth.

Related Questions & Answers

1. What QC certifications should a Headache Cooling Patch Manufacturer have?

ISO 13485 and GMP certification indicate medical-grade production standards.

2. How can I ensure my OEM uses safe materials?

Request MSDS, COA reports, allergen testing, and dermatological certification.

3. Why is QC important for Private Label Headache Cooling Patch brands?

Because manufacturing flaws become your branded responsibility—even if OEM-produced.

4. How is quality tested in cooling patch production?

Through gel stability tests, viscosity measurement, microbiology testing, and adhesion performance checks.

5. What QC checks are needed for Custom Headache Cooling Patch development?

Prototyping verification, ingredient safety assessment, cooling duration simulation, and stability aging tests.

6. What happens if QC is neglected?

Higher defect rates, customer complaints, negative reviews, and damaged brand reputation.