Quality Control in Cooling Relief Gel Patches OEM: What You Need to Know

In the wellness and healthcare product industry, cooling relief gel patches are rapidly gaining recognition as safe, convenient, and effective solutions for managing fever, headaches, muscle tension, and daily stress. With global demand rising, businesses looking to enter or expand in this market often turn to cooling relief gel patches OEM partnerships.

However, the key factor that determines whether your brand succeeds in this space is quality control. Consumers trust products that are safe, consistent, and effective. Any lapse in quality could damage a company’s reputation and result in costly recalls. That’s why understanding quality assurance processes when working with a cooling relief gel patches Manufacturer or Supplier is critical.

This article explores the essential aspects of quality control in OEM manufacturing, the role it plays in developing Custom cooling relief gel patches and Private Label cooling relief gel patches, and how brands can safeguard their market reputation through stringent standards.

1. Why Quality Control Matters in Cooling Relief Gel Patches OEM

When consumers purchase a cooling relief gel patch, they expect:

Immediate Cooling Effect: Relief from fever or discomfort within minutes.

Safe Formulation: Non-toxic, hypoallergenic, and dermatologically tested.

Strong Adhesion: Patches that stay in place without causing skin irritation.

Consistent Performance: Identical results across all batches.

These expectations can only be met through strict quality control. Partnering with a professional cooling relief gel patches Manufacturer ensures products comply with international safety standards and meet consumer demands consistently. Poorly managed quality can lead to:

Customer complaints and product returns

Damage to brand reputation

Regulatory penalties and recalls

Long-term financial losses

In the competitive wellness industry, quality is not optional—it’s the foundation of brand trust and growth.

2. Key Quality Control Measures in Cooling Relief Gel Patches Manufacturing

A trusted cooling relief gel patches Supplier integrates rigorous quality control across every stage of the production cycle. These steps include:

a) Raw Material Testing

Ingredient Purity: Water, gel bases, menthol, herbal extracts, and adhesives are tested for contaminants.

Safety Standards: Materials must be free from heavy metals, allergens, and toxic substances.

b) Formulation Development

Stability Tests: Ensuring gel composition remains effective under different temperatures and humidity levels.

Dermatological Testing: Evaluating potential skin irritation or allergic reactions.

c) Production Process Control

Automated Mixing and Coating: Ensures consistent gel thickness and distribution.

Precision Cutting and Packaging: Maintains accurate patch dimensions and hygienic sealing.

d) Finished Product Testing

Adhesion Strength: Patches must stick securely without discomfort.

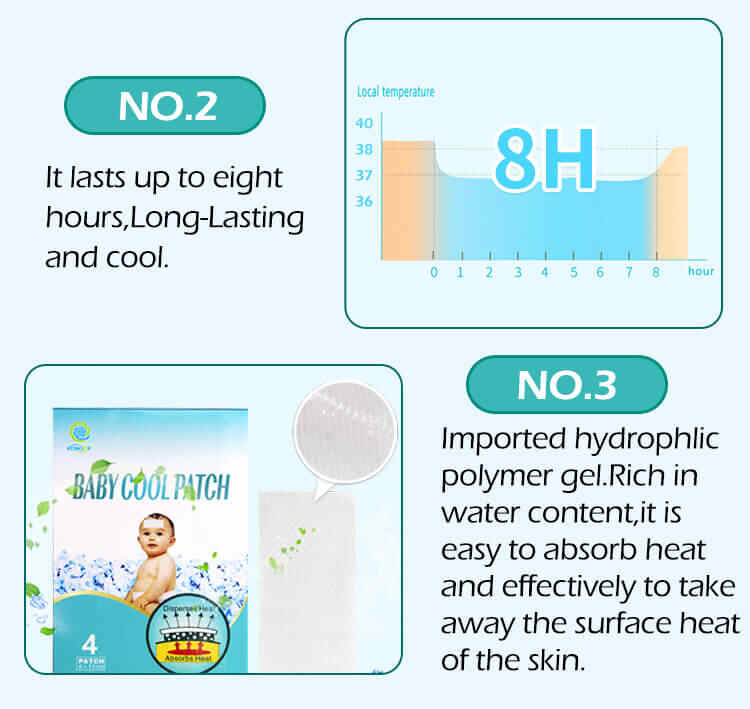

Cooling Duration: Verified effectiveness for the intended period (e.g., 6–10 hours).

Shelf-Life Testing: Ensures long-term stability in storage.

e) Regulatory Compliance

Compliance with GMP (Good Manufacturing Practice), ISO certifications, FDA guidelines, and CE markings where applicable.

By adhering to these steps, a professional cooling relief gel patches OEM ensures safe, reliable, and market-ready products.

3. Quality Assurance in Custom Cooling Relief Gel Patches

For brands seeking Custom cooling relief gel patches, quality control becomes even more vital. Customization may include:

Special Ingredients: Herbal extracts, essential oils, or hypoallergenic formulas.

Unique Sizes and Shapes: For children, athletes, or specific body areas.

Extended Cooling Duration: Patches designed for overnight use.

Fragrance Variations: Lavender, eucalyptus, or mint-infused products.

Each customization requires additional testing to confirm:

Ingredient safety and stability

Adhesive performance with new shapes or formulations

Packaging durability for unique branding designs

Working with an experienced cooling relief gel patches Manufacturer ensures that customization doesn’t compromise safety or effectiveness.

4. Private Label Cooling Relief Gel Patches and Quality Standards

Private Label cooling relief gel patches are a fast way for brands to expand their product range. However, businesses must ensure that the cooling relief gel patches Supplier maintains:

Consistent Batch Quality: Every batch should perform identically.

Proven Safety Records: Documentation of dermatological and safety tests.

Transparent Quality Reports: Clear evidence of compliance with global standards.

High-quality private label solutions allow brands to focus on marketing and distribution while being confident in product safety and effectiveness.

5. The Role of Certifications in OEM Quality Control

Certifications serve as proof that your chosen cooling relief gel patches OEM adheres to international standards. Essential certifications include:

ISO 13485: Specific to medical device quality management.

GMP Certification: Ensures consistent production and quality standards.

CE Marking: Compliance for sale in the European Union.

FDA Registration: Required for U.S. market entry.

By choosing a certified cooling relief gel patches Manufacturer, brands reduce risks of compliance issues and gain consumer trust more quickly.

6. How Quality Control Impacts Brand Reputation

The wellness industry thrives on consumer trust. A single negative experience can lead to negative reviews and brand damage. Strong quality control provides:

Consumer Confidence: Customers trust brands with consistent product quality.

Reduced Returns: Fewer complaints and higher satisfaction rates.

Positive Brand Image: Reliable products create repeat buyers.

Market Expansion: Regulatory compliance makes it easier to sell internationally.

This is why leading brands rely on experienced cooling relief gel patches OEM partners—they know quality assurance directly affects long-term success.

7. How to Choose the Right Cooling Relief Gel Patches OEM Partner

When selecting a partner, businesses should evaluate:

Manufacturing Facilities: Modern, hygienic, and equipped for high-volume production.

Testing Capabilities: In-house laboratories or partnerships with certified testing agencies.

Customization Options: Ability to produce both Custom cooling relief gel patches and Private Label cooling relief gel patches.

Supply Chain Reliability: Strong logistics support from a dependable cooling relief gel patches Supplier.

Transparency: Clear documentation and regular quality audits.

Choosing the right OEM partner is not just about cost—it’s about ensuring long-term reliability and growth.

8. Conclusion

As the demand for cooling relief gel patches continues to rise, quality control becomes the single most important factor in building a successful brand. Whether you are creating Custom cooling relief gel patches or launching Private Label cooling relief gel patches, partnering with an experienced and certified cooling relief gel patches Manufacturer is essential.

A trustworthy cooling relief gel patches Supplier ensures your products meet global safety standards, deliver consistent performance, and strengthen consumer trust. In the competitive health and wellness market, OEM quality control is not just a process—it’s a business strategy that drives growth and brand success.

Related Questions and Answers

Q1: Why is quality control important in cooling relief gel patches OEM?

A1: It ensures safety, consistency, and effectiveness, protecting both consumers and brand reputation.

Q2: What certifications should a cooling relief gel patches Manufacturer have?

A2: Key certifications include ISO 13485, GMP, CE marking, and FDA registration.

Q3: How are Custom cooling relief gel patches tested for quality?

A3: They undergo additional safety, stability, and performance testing due to unique formulations or designs.

Q4: What are the risks of poor quality control in Private Label cooling relief gel patches?

A4: Risks include recalls, regulatory penalties, negative reviews, and long-term brand damage.

Q5: How does a cooling relief gel patches Supplier support quality assurance?

A5: A reliable supplier ensures consistent batch quality, timely deliveries, and transparent documentation.