How to Ensure Quality Control in Fever Cooling Patch OEM Production?

In today’s highly competitive health and wellness market, fever cooling patch OEM production must not only meet increasing demand but also maintain strict quality control standards. Whether you’re a fever cooling patch manufacturer, a brand looking for private label fever cooling patch solutions, or a buyer seeking a reliable fever cooling patch supplier, understanding how quality control is managed is critical. Quality control directly impacts product safety, efficacy, customer satisfaction, and brand reputation.

This article explores the core strategies and best practices for ensuring top-tier quality control in OEM fever cooling patch production, aligning with modern consumer expectations and regulatory standards.

1. The Importance of Quality Control in OEM Fever Cooling Patch Production

The global demand for custom fever cooling patch solutions has skyrocketed, especially as parents and caregivers seek safe, effective, and non-invasive fever management options. However, without stringent quality control, even a promising product can lead to recalls, health risks, or damage to your brand’s credibility.

Key reasons quality control matters:

Ensures consistent effectiveness and safety of each batch.

Guarantees compliance with national and international health standards.

Enhances brand trust and customer retention.

Minimizes product defects, wastage, and production costs.

2. Selecting a Certified and Reputable Fever Cooling Patch Manufacturer

The first step in ensuring quality control begins with choosing the right fever cooling patch manufacturer. An experienced OEM with certifications and a proven track record can implement better processes from raw material sourcing to packaging.

Certifications to look for:

ISO 13485 (Quality Management System for Medical Devices)

CE certification (for the European market)

FDA registration (for the U.S. market)

GMP compliance (Good Manufacturing Practices)

A reputable fever cooling patch OEM will not only have these certifications but will also be transparent with documentation and willing to undergo third-party audits if needed.

3. Raw Material Quality Assurance

The core components of a fever cooling patch include hydrogel, cooling agents, adhesives, and protective film. Each of these must be non-toxic, hypoallergenic, and safe for skin contact—especially since the patches are often used on children.

Best practices in raw material control:

Partner only with audited raw material suppliers.

Test each batch of materials for microbial contamination, toxicity, and consistency.

Store raw materials in controlled environments to avoid degradation.

A quality fever cooling patch supplier should provide material traceability reports to ensure accountability at every production stage.

4. In-Process Monitoring and Testing

In the OEM manufacturing process, constant monitoring is key to maintaining product uniformity and performance.

Key in-process quality checks include:

Viscosity and pH testing of the hydrogel.

Adhesion strength testing to ensure the patch stays on the skin but peels off without irritation.

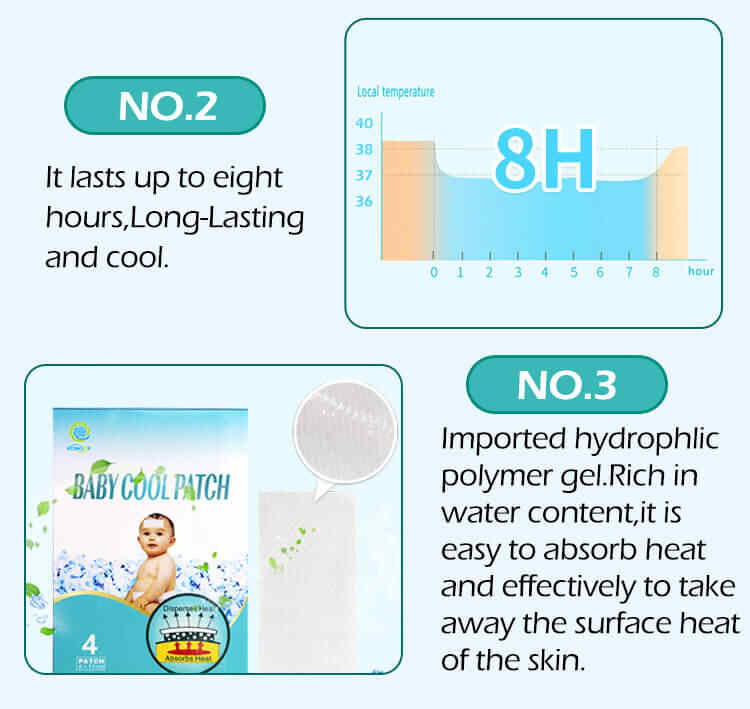

Cooling effect duration and consistency checks.

Size and thickness control for each patch.

Modern fever cooling patch OEM facilities use automated systems and real-time data tracking to detect anomalies early in the production line.

5. Final Product Testing and Batch Release

Before a batch is released to market or sent to a private label partner, final inspections must verify that the product meets every required specification.

Final quality control tests:

Visual inspection for defects, discoloration, or improper packaging.

Functionality test to confirm the patch maintains cooling for the stated duration.

Skin irritation testing on human volunteers or through certified labs.

Shelf life stability testing to ensure long-term efficacy.

OEMs offering custom fever cooling patch services often run specialized performance tests aligned with a brand’s market needs and regulations.

6. Packaging and Labeling Accuracy

High-quality packaging protects the product during shipping and enhances consumer confidence. Furthermore, regulatory bodies strictly require proper labeling, especially for health products.

Packaging control points:

Check for tamper-evident sealing.

Ensure labels meet country-specific regulatory requirements (e.g., ingredients, warnings, usage instructions).

Confirm private label details are correct (brand name, batch number, expiry date).

A private label fever cooling patch partner must guarantee that packaging meets both functional and branding needs without compromising on quality.

7. Continuous Improvement Through Feedback and Audits

Quality control doesn’t end at product release. A strong fever cooling patch manufacturer continuously collects customer feedback and internal audit data to improve processes.

How top OEMs stay ahead:

Conduct routine internal audits and third-party inspections.

Use customer complaints and feedback for root cause analysis.

Train staff regularly on updated quality procedures.

This feedback loop is essential for maintaining competitive advantage and trust as a reliable fever cooling patch supplier.

8. Benefits of Partnering with a Quality-Focused Fever Cooling Patch OEM

Choosing an OEM with advanced quality control systems brings significant advantages for brands, retailers, and distributors:

Brand credibility: Safe and effective patches strengthen consumer trust.

Regulatory compliance: Smooth entry into international markets.

Customization flexibility: Tailored formulations and packaging without compromising on standards.

Lower risk: Fewer recalls, legal issues, or customer dissatisfaction.

Operational efficiency: Reduced waste, rework, and faster time-to-market.

Conclusion

Quality control in fever cooling patch OEM production is not an optional step—it’s a critical foundation for success. From selecting the right fever cooling patch manufacturer and sourcing safe raw materials, to implementing strict in-process controls and final product testing, each stage plays a vital role.

For any brand seeking custom fever cooling patch or private label fever cooling patch solutions, aligning with a fever cooling patch supplier that emphasizes quality assurance is the smartest investment.

Related Questions and Answers

Q1: What certifications should a fever cooling patch OEM have?

A1: Look for ISO 13485, CE, GMP, and FDA compliance to ensure international quality and safety standards.

Q2: Can I request specific quality tests for my private label fever cooling patch?

A2: Yes. A good fever cooling patch OEM will accommodate customized testing based on your target market and branding needs.

Q3: How often are raw materials tested in OEM production?

A3: Reputable manufacturers test every batch for consistency, microbial safety, and physical-chemical parameters.

Q4: How can I verify the quality of a fever cooling patch supplier before working with them?

A4: Request audit reports, third-party test certificates, and client references. Site visits are also recommended.

Q5: What’s the risk of working with an unverified fever cooling patch manufacturer?

A5: Risks include substandard products, regulatory penalties, customer dissatisfaction, and damage to brand reputation.