How Long Does It Take to Produce Customized Inflammation Relief Patches?

Producing Custom Inflammation Relief Patches involves a multi-stage process that varies depending on product complexity, branding requirements, and your chosen Inflammation Relief Patches Manufacturer. Whether you're launching a Private Label Inflammation Relief Patches line or collaborating with an Inflammation Relief Patches OEM for a completely tailored formulation, understanding the typical production timeline is critical to proper planning and execution.

In this comprehensive guide, we'll explore each phase of the production timeline, factors that impact lead times, and how working with the right Inflammation Relief Patches Supplier can streamline the journey from concept to shelf-ready product.

Understanding the Custom Patch Production Process

The total time it takes to produce customized inflammation relief patches typically ranges between 6 to 12 weeks from concept to completion. However, this timeline can be shorter or longer depending on several variables.

Here’s a breakdown of the typical phases:

1. Product Planning & OEM Consultation (1–2 Weeks)

The journey starts with defining the project scope. You’ll consult with an Inflammation Relief Patches OEM to discuss your needs, such as:

Target market

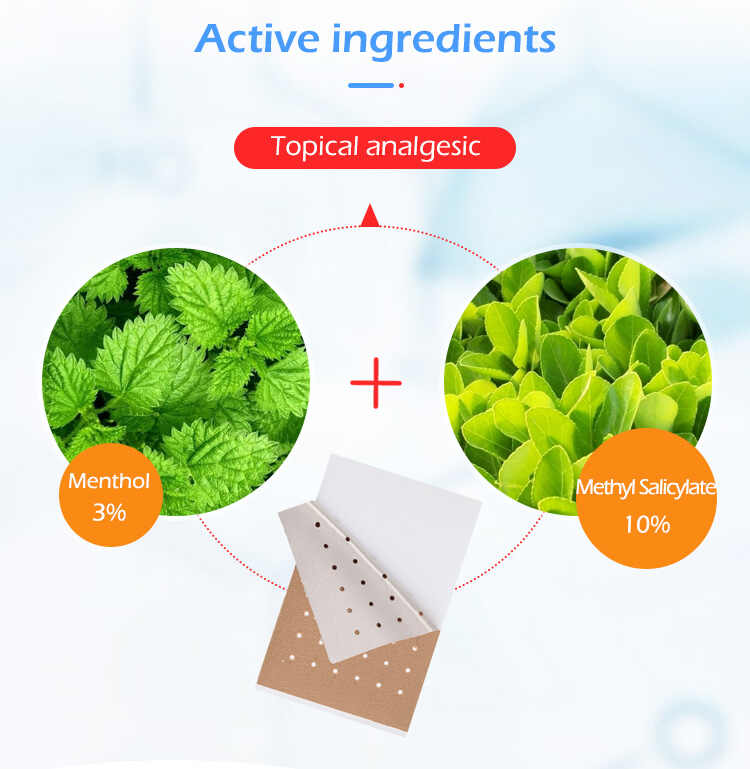

Desired active ingredients (e.g., menthol, turmeric, CBD)

Patch size, shape, and adhesion strength

Regulatory requirements

MOQ (Minimum Order Quantity)

Branding and packaging ideas

During this stage, the Inflammation Relief Patches Manufacturer will assess feasibility, provide input on formulations, and recommend solutions based on your goals and budget.

Timeframe: 1–2 weeks

2. Formulation Development (2–3 Weeks)

If you choose to develop Custom Inflammation Relief Patches, the OEM will begin formulation development. This includes:

Ingredient selection based on therapeutic claims

Determining optimal dosage and release rate

Ensuring skin safety and patch adhesion

Experienced Inflammation Relief Patches Suppliers with in-house R&D can often complete this process more quickly.

For clients who choose existing formulations from the manufacturer’s catalog, this step may be skipped or shortened.

Timeframe: 0–3 weeks depending on whether a custom formula is needed

3. Sample Creation & Testing (1–3 Weeks)

Once the formula is ready, the OEM creates sample patches for evaluation. You’ll test the patches for:

Efficacy

Comfort and wear time

Skin compatibility

Scent and aesthetics

You may request adjustments, which could add another round of sampling.

Timeframe: 1–3 weeks (may require multiple rounds)

4. Packaging & Branding Development (1–2 Weeks)

Your Private Label Inflammation Relief Patches need personalized branding. During this phase, the OEM may assist with:

Designing the pouch, box, and master carton

Finalizing brand logo, instructions, and regulatory text

Labeling based on destination market requirements

An experienced Inflammation Relief Patches Manufacturer can offer ready-to-customize design templates to accelerate the process.

Timeframe: 1–2 weeks

5. Production & Quality Control (2–4 Weeks)

Once the product and packaging are approved, manufacturing begins. Production typically involves:

Ingredient sourcing (may delay production if rare ingredients are used)

Batch manufacturing under GMP standards

Patch die-cutting, saturation, drying, sealing

Packaging and final assembly

Product quality testing (microbial limits, adhesive consistency, etc.)

Reliable Inflammation Relief Patches Suppliers conduct multiple QC checks to ensure every batch is consistent and compliant.

Timeframe: 2–4 weeks

6. Logistics & Shipping (1–3 Weeks)

After production, your patches are packed and prepared for shipment. Shipping time varies by:

Destination country

Shipping method (air vs. sea)

Customs clearance

Some Inflammation Relief Patches OEMs offer warehousing and global logistics support.

Timeframe: 1–3 weeks depending on location and logistics arrangements

Total Production Timeline Summary

| Stage | Estimated Time |

|---|---|

| Planning & Consultation | 1–2 weeks |

| Formulation Development | 0–3 weeks |

| Sample Creation & Testing | 1–3 weeks |

| Branding & Packaging Design | 1–2 weeks |

| Production & Quality Control | 2–4 weeks |

| Logistics & Shipping | 1–3 weeks |

| Total | 6–12 weeks average |

Factors That Influence Production Time

1. Level of Customization

The more custom your formulation and packaging, the longer the production cycle. Choosing a stock base formula can significantly reduce development time.

2. MOQ and Production Volume

Larger batch sizes may take longer to manufacture, especially if the OEM has multiple clients in queue.

3. Ingredient Availability

Rare or seasonal herbal extracts may extend the ingredient sourcing timeline.

4. Regulatory Compliance

If your product needs to comply with FDA (U.S.), CE (Europe), or other local guidelines, additional testing and documentation may be required.

5. OEM Capacity

Well-established Inflammation Relief Patches Manufacturers with scalable infrastructure and automated production lines can typically fulfill orders faster than smaller facilities.

How to Shorten Production Time

If speed-to-market is a priority, consider the following:

Use existing formulations from your Inflammation Relief Patches Supplier

Work with an OEM that offers in-house design and R&D

Choose standardized packaging options

Place orders during off-peak manufacturing seasons

Ensure timely feedback on samples and artwork approvals

Benefits of Working with a High-Quality Inflammation Relief Patches Manufacturer

✅ Faster Turnaround

Established manufacturers have streamlined processes, experienced staff, and access to raw materials to speed up production.

✅ End-to-End Services

A one-stop Inflammation Relief Patches OEM can manage formulation, production, labeling, and logistics—all in-house.

✅ Regulatory Confidence

Reliable suppliers provide compliance documentation, which simplifies your path to market.

✅ Risk Mitigation

Experienced partners help you avoid delays from formulation errors, packaging misprints, or regulatory non-compliance.

Key OEM Selection Checklist

To ensure a smooth and timely production process, look for an OEM partner that:

Specializes in Custom Inflammation Relief Patches

Offers low MOQs for startups and scalable volume for growth

Holds GMP/ISO/FDA/CE certifications

Has positive client testimonials and references

Communicates promptly and transparently

Provides a clear production timeline from the start

Frequently Asked Questions

1. How long does it take to produce a private label inflammation relief patch?

It usually takes 6–12 weeks from concept to delivery, depending on the level of customization and the capabilities of the Inflammation Relief Patches OEM.

2. Can I speed up the production process?

Yes, by using existing formulations and packaging options, and choosing a responsive Inflammation Relief Patches Supplier with in-house R&D and production.

3. What is the fastest timeline I can expect?

If you use a ready-made formula and standard packaging, some OEMs can complete production within 4–6 weeks.

4. What causes production delays?

Delays may occur due to ingredient sourcing, slow approvals, packaging errors, or limited OEM capacity.

5. Can I get samples before mass production?

Yes, almost all professional Inflammation Relief Patches Manufacturers provide samples for testing and approval before finalizing the bulk order.

6. Do OEMs handle regulatory compliance?

Yes, trusted OEMs assist with label design, claims verification, MSDS, COA, and other compliance documentation.

Conclusion

Producing Custom Inflammation Relief Patches is a strategic investment in your wellness brand, and understanding the production timeline helps you plan your market entry more effectively. From formulation and branding to testing and shipping, each step can be managed efficiently with the right Inflammation Relief Patches Manufacturer or OEM partner.

The key is to work with a responsive, experienced, and certified Inflammation Relief Patches Supplier who offers transparency, expertise, and full support throughout the process. Whether you’re launching a niche herbal patch or a full-scale private label product line, timing is everything—and preparation is your best asset.