From Concept to Market: Streamlining Your Capsicum Heat Patches OEM Process

Introduction: Unlocking Market Potential with Efficient Capsicum Heat Patches OEM

In today’s competitive wellness market, speed, quality, and innovation are critical for success. If your brand is considering launching Private Label Capsicum Heat Patches or expanding your portfolio with Custom Capsicum Heat Patches, understanding and streamlining the Capsicum Heat Patches OEM process is essential.

Partnering with the right Capsicum Heat Patches Manufacturer and Capsicum Heat Patches Supplier can accelerate your product development, reduce costs, ensure compliance, and ultimately bring your product from concept to market faster and more efficiently.

This article offers an in-depth exploration of the OEM process, providing actionable insights to help your brand navigate each stage effectively and maximize success.

1. Understanding the Capsicum Heat Patches Market Landscape

Before diving into the OEM process, it's crucial to understand why Capsicum Heat Patches are in demand:

They offer natural, effective pain relief through capsaicin-induced heat.

Growing global wellness trends favor drug-free and topical therapies.

Consumers seek convenient, easy-to-use products for muscle and joint discomfort.

The rise of sports and aging populations increases market potential.

Knowing your market helps tailor the OEM process to produce Custom Capsicum Heat Patches that resonate with your target audience.

2. Concept Development: Defining Your Product Vision

The OEM journey begins with a clear concept:

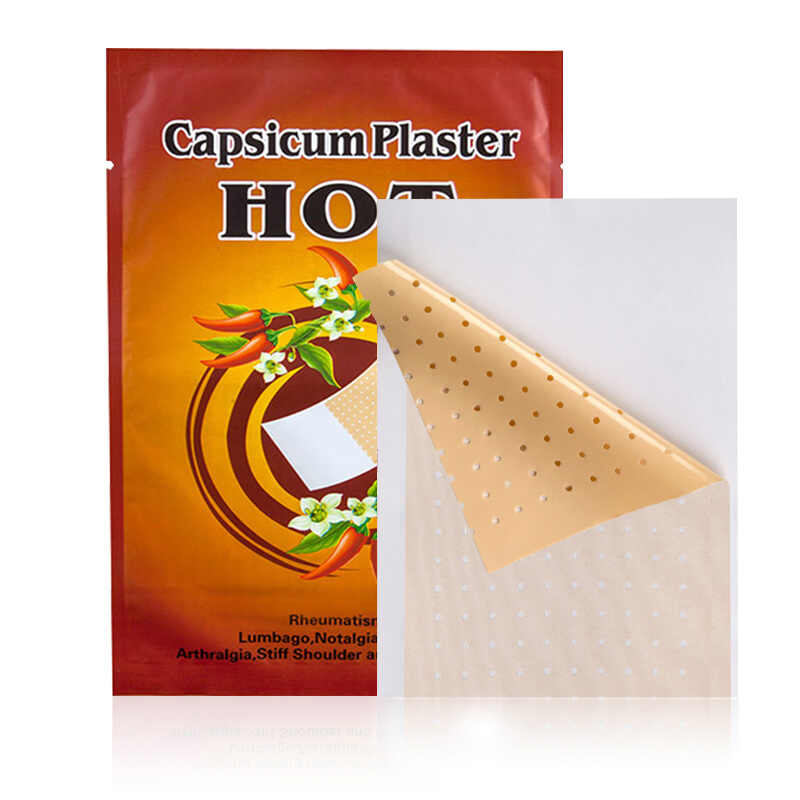

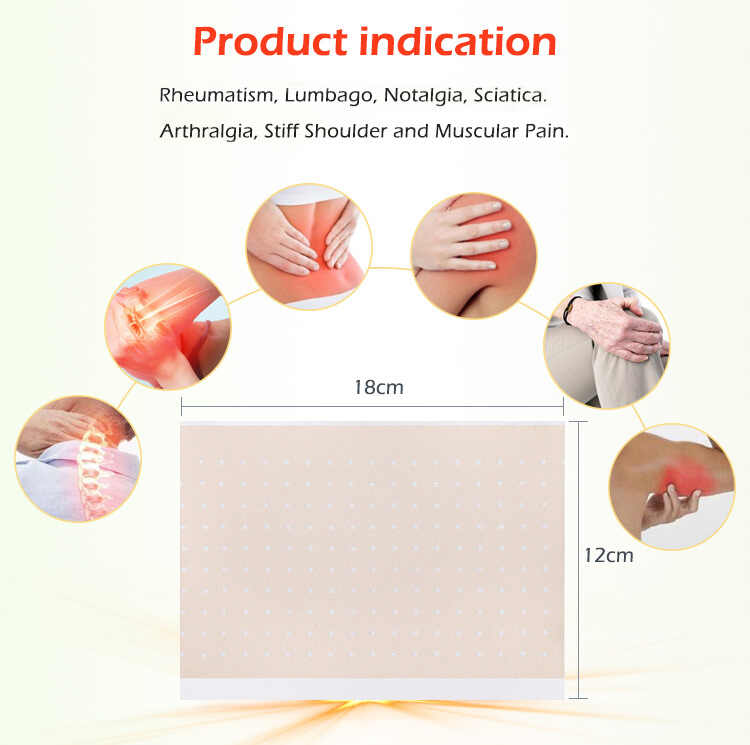

Identify target consumer needs (e.g., patch size, heat duration, herbal additives).

Decide on product positioning: premium, budget-friendly, eco-conscious, etc.

Outline desired features: skin-friendly adhesives, hypoallergenic formulations, or specific heat levels.

Set packaging preferences for your Private Label Capsicum Heat Patches.

Collaborating early with your Capsicum Heat Patches Manufacturer helps align concept feasibility with manufacturing capabilities.

3. Selecting the Right Capsicum Heat Patches Manufacturer and Supplier

Choosing an experienced and reliable Capsicum Heat Patches Supplier is a critical success factor:

Verify certifications: ISO 13485, GMP compliance, and relevant regulatory adherence.

Assess capacity for customization and flexibility in formulation and packaging.

Evaluate quality control processes and testing capabilities.

Review past projects and client testimonials to gauge expertise.

The ideal partner ensures your Capsicum Heat Patches OEM journey is smooth, compliant, and scalable.

4. Product Formulation and Customization

This stage involves refining your Custom Capsicum Heat Patches formula:

Work with your manufacturer’s R&D team to optimize capsaicin concentration for safe, effective heat therapy.

Consider adding complementary herbs (e.g., menthol, ginger) to enhance therapeutic effects.

Choose patch materials that balance adhesion, breathability, and biodegradability if sustainability is a priority.

Conduct patch size and shape testing to maximize user comfort and application areas.

Your Capsicum Heat Patches Supplier should support iteration cycles until the formula and design meet your specifications.

5. Regulatory Compliance and Testing

Ensuring your product complies with regulatory standards is essential to avoid delays and penalties:

Confirm product classification as medical device or wellness product in your target markets.

Ensure the manufacturer follows GMP and relevant ISO standards.

Arrange biocompatibility testing (ISO 10993) to verify skin safety.

Conduct stability, adhesion, and efficacy testing to guarantee performance.

Prepare all necessary technical documentation and labeling per FDA, CE, or other regional requirements.

A knowledgeable Capsicum Heat Patches Manufacturer will guide you through compliance to ease your market entry.

6. Packaging Design and Branding for Private Label Capsicum Heat Patches

Packaging is a crucial touchpoint for customers:

Collaborate with your OEM partner to design eco-friendly, attractive, and informative packaging.

Include clear instructions, warnings, and ingredient disclosures to meet regulations.

Consider minimalistic or premium branding aligned with your market positioning.

Explore sustainable packaging options to appeal to eco-conscious consumers.

Well-designed packaging boosts shelf impact and supports your brand’s storytelling.

7. Manufacturing and Quality Control

Once the formula and packaging are finalized, production begins:

Choose batch sizes appropriate for your launch and forecast.

Ensure rigorous quality control at every stage—raw material inspection, in-process testing, and final product audits.

Track batch numbers for traceability.

Monitor production timelines closely to meet launch schedules.

A capable Capsicum Heat Patches Supplier will maintain consistency and prevent quality issues during scaling.

8. Logistics, Inventory, and Distribution

Efficient logistics ensures product availability and customer satisfaction:

Plan inventory levels with your manufacturer to avoid stockouts or overproduction.

Coordinate shipping, customs clearance, and warehousing as needed.

Consider demand forecasting tools integrated with your Capsicum Heat Patches OEM partner.

Prepare for product replenishment based on sales velocity.

Strategic inventory management supports timely market supply and positive brand reputation.

9. Launch Strategy and Post-Launch Optimization

With products ready, focus on market entry:

Develop a marketing campaign highlighting your Private Label Capsicum Heat Patches’ unique benefits.

Use influencer partnerships, educational content, and social proof to build credibility.

Collect customer feedback and reviews to identify improvement areas.

Work with your Capsicum Heat Patches Supplier for continuous improvement and formulation updates.

A feedback loop helps refine your products and strengthens customer loyalty.

10. Conclusion: The Power of Streamlined Capsicum Heat Patches OEM

Streamlining your Capsicum Heat Patches OEM process from concept to market positions your brand for sustainable growth in the wellness sector. By selecting the right Capsicum Heat Patches Manufacturer, prioritizing quality and compliance, and leveraging customization opportunities, you can deliver products that resonate with consumers and outperform competitors.

Efficient OEM collaboration reduces risk, shortens time to market, and amplifies your brand’s ability to respond to evolving consumer trends.

Embrace this strategic approach to develop and launch Custom Capsicum Heat Patches and Private Label Capsicum Heat Patches that not only relieve pain but also elevate your brand in the crowded wellness marketplace.

Related Questions and Short Answers

Q1: What is the typical timeline for Capsicum Heat Patches OEM?

A: Usually 60 to 90 days from concept to production, depending on customization and testing requirements.

Q2: How do I choose the best Capsicum Heat Patches Manufacturer?

A: Look for certifications, customization capabilities, proven quality control, and experience in international compliance.

Q3: Can I customize the formula and packaging for Private Label Capsicum Heat Patches?

A: Yes, OEM partners typically offer extensive customization options tailored to your brand.

Q4: What regulatory standards apply to Capsicum Heat Patches OEM?

A: FDA, CE marking, ISO 13485, GMP, and biocompatibility standards like ISO 10993 are commonly required.

Q5: How do I ensure quality throughout manufacturing?

A: Choose a supplier with strict quality control processes, batch traceability, and third-party testing.

Q6: Is sustainable packaging available for Capsicum Heat Patches?

A: Yes, many OEM manufacturers offer eco-friendly packaging options to meet consumer and regulatory demands.