Cost vs. Performance: How OEM Sunburn Cooling Patches Balance Cooling Effect and Profit Margins

As global demand for after-sun care products continues to grow, Sunburn Cooling Patches have emerged as a high-potential category combining functional skincare with rapid relief benefits. For brands entering or expanding in this market, one critical question dominates sourcing decisions:

How can Sunburn Cooling Patches OEM solutions deliver strong cooling performance without eroding profit margins?

Balancing cost and performance is not accidental—it is the result of formulation science, material engineering, production efficiency, and strategic decision-making by an experienced Sunburn Cooling Patches Manufacturer. This article explores how OEM manufacturers optimize cooling effectiveness while maintaining competitive pricing, helping brands succeed with Custom Sunburn Cooling Patches and Private Label Sunburn Cooling Patches worldwide.

1. Why Cost vs. Performance Matters in Sunburn Cooling Patches

In highly competitive global markets, consumers expect:

Immediate cooling sensation

Long-lasting soothing relief

Skin safety and comfort

Affordable retail pricing

At the same time, brands must protect:

Gross margins

Marketing budgets

Distribution incentives

This creates a direct tension between performance enhancement and cost control. A professional Sunburn Cooling Patches OEM understands that superior products are not defined by maximum ingredient cost, but by optimized performance per unit cost.

2. Understanding Cooling Performance: What Really Drives Effectiveness?

Before discussing cost, it is essential to understand what determines cooling performance in Sunburn Cooling Patches.

2.1 Key Factors Affecting Cooling Effect

Cooling effectiveness is influenced by:

Hydrogel composition and water retention

Cooling agents (menthol, polyols, phase-change materials)

Patch thickness and surface area

Breathability and skin adhesion

Release rate of cooling components

An experienced Sunburn Cooling Patches Manufacturer fine-tunes these variables to achieve perceived cooling intensity, not just laboratory cooling values.

2.2 Perception vs. Absolute Cooling

One important OEM insight:

Consumer perception matters more than absolute temperature reduction.

A well-designed Custom Sunburn Cooling Patches formula can deliver a strong sensory cooling effect using optimized concentrations, rather than expensive over-formulation. This is where OEM expertise significantly protects margins.

3. Cost Structure of OEM Sunburn Cooling Patches

To understand margin optimization, brands must first understand the cost breakdown.

3.1 Core Cost Components

Typical cost elements include:

Raw materials (hydrogel, cooling agents, backing film)

Packaging materials

Labor and manufacturing overhead

Quality control and testing

Regulatory compliance costs

A transparent Sunburn Cooling Patches Supplier helps brands analyze which components impact cost most—and which offer room for optimization.

3.2 Raw Materials: The Largest Cost Lever

Raw materials often represent 40–60% of total production cost. However, higher raw material cost does not always equal better performance.

An experienced Sunburn Cooling Patches OEM focuses on:

Functional efficiency per ingredient

Synergistic ingredient combinations

Stable, scalable sourcing

This approach ensures consistent cooling performance without unnecessary cost inflation.

4. How OEM Manufacturers Optimize Cooling Agents

4.1 Smart Selection of Cooling Ingredients

Cooling agents vary widely in cost and effect. A professional Sunburn Cooling Patches Manufacturer evaluates:

Cooling onset speed

Duration of effect

Skin tolerance

Regulatory acceptance

Instead of relying solely on high-cost ingredients, OEMs often blend moderate-cost cooling agents to achieve equal or better perceived performance.

4.2 Dosage Optimization

More is not always better. Excessive cooling agents may:

Increase irritation risk

Raise regulatory complexity

Inflate raw material cost

OEM manufacturers conduct formulation trials to identify the optimal dosage window, ensuring performance while protecting margins for Private Label Sunburn Cooling Patches.

5. Hydrogel Engineering: Performance Without Excess Cost

5.1 Hydrogel Quality vs Quantity

The hydrogel matrix is the foundation of Sunburn Cooling Patches. Key considerations include:

Water retention capacity

Cooling transfer efficiency

Skin conformity

Rather than increasing gel thickness (which raises cost), a skilled Sunburn Cooling Patches OEM improves gel structure and cross-linking, enhancing performance with minimal material increase.

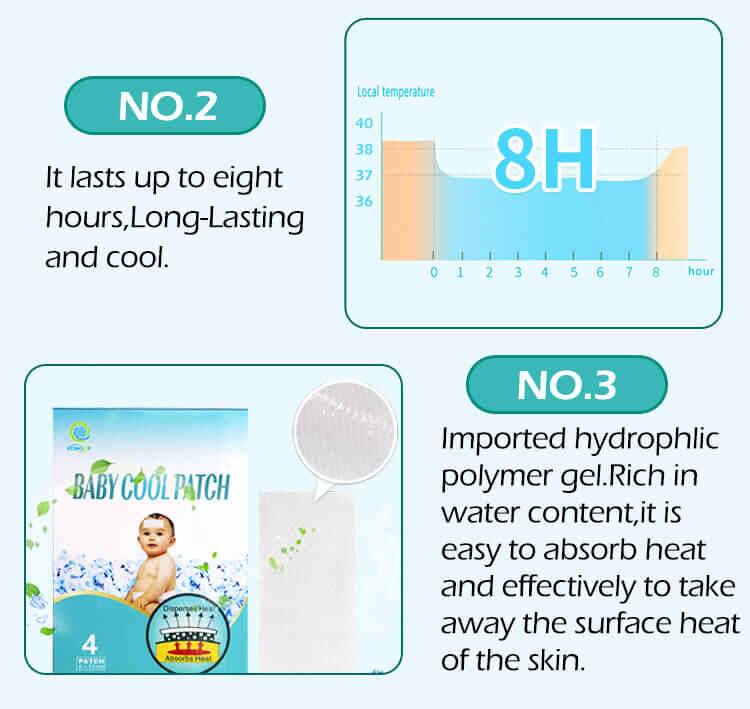

5.2 Long-Lasting Cooling at Lower Cost

By improving moisture retention and evaporation control, OEM manufacturers can extend cooling duration without adding expensive active ingredients—an essential strategy for margin preservation.

6. Manufacturing Efficiency as a Margin Protector

6.1 Automation and Scale Advantages

Large-scale Sunburn Cooling Patches Manufacturers invest in:

Automated coating and cutting lines

Precision dosing systems

Reduced material waste

These efficiencies significantly lower unit costs, enabling brands to offer competitive pricing without sacrificing cooling performance.

6.2 Yield Control and Defect Reduction

Higher yields mean lower cost per unit. OEM manufacturers with mature quality systems reduce:

Gel inconsistencies

Adhesion failures

Packaging defects

This directly improves profitability for Sunburn Cooling Patches Supplier partners.

7. Customization Without Cost Explosion

7.1 Smart Custom Sunburn Cooling Patches Design

Customization does not have to be expensive. A strategic Sunburn Cooling Patches OEM offers:

Modular formulation options

Standard base gels with customized cooling levels

Flexible packaging designs

This allows brands to differentiate Custom Sunburn Cooling Patches while leveraging shared production efficiencies.

7.2 Private Label Strategies That Protect Margins

For Private Label Sunburn Cooling Patches, OEMs often recommend:

Proven base formulations

Pre-approved materials

Standardized production workflows

This shortens development cycles and reduces compliance costs—key drivers of long-term profitability.

8. Performance Testing vs Over-Engineering

8.1 Data-Driven Performance Validation

OEM manufacturers rely on:

Sensory testing

Skin compatibility studies

Real-world user feedback

Instead of over-engineering products, they focus on validated performance thresholds that meet consumer expectations at optimal cost.

8.2 Avoiding “Invisible” Cost Increases

Some performance enhancements are not perceived by consumers. A professional Sunburn Cooling Patches Manufacturer avoids investing in features that add cost without marketing or user benefit.

9. Regulatory Compliance and Its Cost Impact

Compliance affects margins more than many brands realize.

A compliant Sunburn Cooling Patches OEM helps brands:

Avoid reformulation delays

Reduce testing redundancy

Prevent customs rejections

Smooth regulatory pathways protect both time-to-market and profit margins.

10. Choosing the Right Sunburn Cooling Patches Supplier

When balancing cost and performance, supplier selection is critical.

Key questions to ask a Sunburn Cooling Patches Supplier:

How do you optimize cooling performance at different price levels?

Can you provide multiple formulation tiers?

What cost-saving strategies do you use without reducing quality?

How scalable is your production?

A strategic supplier is a profit partner, not just a manufacturer.

11. Cost vs Performance as a Brand Strategy

Brands that succeed long-term do not chase the lowest cost or the highest specs—they pursue optimal value.

With the right Sunburn Cooling Patches Manufacturer, brands can:

Launch competitively priced products

Maintain consistent cooling performance

Scale globally with confidence

This balance is the true competitive advantage in the sunburn care market.

Conclusion: OEM Expertise Turns Cost Pressure into Opportunity

In the Sunburn Cooling Patches market, cost pressure is inevitable—but margin erosion is not.

By partnering with an experienced Sunburn Cooling Patches OEM, brands can transform formulation science, manufacturing efficiency, and customization strategy into a powerful balance of cooling performance and profitability.

Whether developing Custom Sunburn Cooling Patches or expanding a Private Label Sunburn Cooling Patches line, success depends on choosing a Sunburn Cooling Patches Supplier that understands both science and business.

Frequently Asked Questions (FAQ)

Q1: Do higher-cost cooling agents always perform better?

A: No. Performance depends on formulation synergy, not ingredient price alone.

Q2: Can a Sunburn Cooling Patches OEM offer different cost tiers?

A: Yes. Professional OEMs provide multiple performance-cost options.

Q3: Are Private Label Sunburn Cooling Patches less effective?

A: Not necessarily. Many use proven OEM formulations with excellent performance.

Q4: How does manufacturing scale affect margins?

A: Larger scale reduces unit cost while maintaining consistent quality.

Q5: What is the biggest cost mistake brands make?

A: Over-engineering features that consumers do not perceive or value.