Are Custom Pain Relief Gel Patches More Expensive Than Standard Options?

Understanding the Cost Structure and Long-Term Value of Custom vs. Standard Pain Relief Gel Patches

Introduction

As the market for pain management products grows rapidly, businesses face a critical decision: Should you invest in Custom Pain Relief Gel Patches or stick with standard or Private Label Pain Relief Gel Patches? The cost is often a deciding factor, but pricing alone doesn't tell the full story.

In this article, we explore whether Custom Pain Relief Gel Patches are indeed more expensive than standard options — and more importantly, whether the higher upfront investment can lead to greater long-term rewards. We’ll also break down the role of Pain Relief Gel Patches Manufacturers, OEM partnerships, and Pain Relief Gel Patches Suppliers in shaping your pricing and product strategy.

1. Understanding the Difference: Custom vs. Standard Pain Relief Gel Patches

What Are Standard (or Private Label) Pain Relief Gel Patches?

Standard or Private Label Pain Relief Gel Patches are pre-formulated products manufactured by a Pain Relief Gel Patches Supplier and sold under your brand name. These products are already tested, proven, and ready for market — ideal for businesses looking for a fast, cost-effective launch.

Key Traits:

Predefined formulation and format

Limited customization (mostly in branding and packaging)

Shorter lead time

Lower R&D investment

What Are Custom Pain Relief Gel Patches?

Custom Pain Relief Gel Patches, often created through a Pain Relief Gel Patches OEM partnership, are formulated based on your unique specifications. You control the active ingredients, scent, adhesive strength, size, and more — making it ideal for brands seeking differentiation and innovation.

Key Traits:

Tailored formulations and product specs

Higher flexibility in materials and ingredients

Built from scratch in collaboration with the Pain Relief Gel Patches Manufacturer

Requires R&D, prototyping, and testing

2. Cost Comparison: Are Custom Gel Patches Really More Expensive?

Initial Production Costs

| Cost Element | Custom Pain Relief Gel Patches | Standard (Private Label) Patches |

|---|---|---|

| R&D and formulation | ✅ Yes – often significant | ❌ None – already developed |

| Material selection | ✅ Fully controlled (premium or niche) | ❌ Fixed by supplier |

| Sampling and testing | ✅ Required (clinical, stability, etc.) | ❌ Already completed |

| Tooling (molds, dies) | ✅ Possible for unique shapes | ❌ Standardized |

| MOQ (Minimum Order Quantity) | ✅ Higher, typically 10,000+ | ❌ Lower, sometimes 3,000 |

Unit Cost Per Patch

Once the development phase is complete, the unit cost of Custom Pain Relief Gel Patches can be comparable — or even lower — if ordered in large quantities.

Factors influencing cost-per-unit:

Batch volume (higher volume = lower per unit)

Ingredient sourcing (synthetic vs. herbal vs. patented actives)

Type of packaging (pouch, box, retail-ready)

Production location (local vs. overseas Pain Relief Gel Patches Manufacturer)

3. Factors That Justify the Higher Cost of Custom Pain Relief Gel Patches

A. Brand Differentiation

Custom formulations allow your product to stand out with:

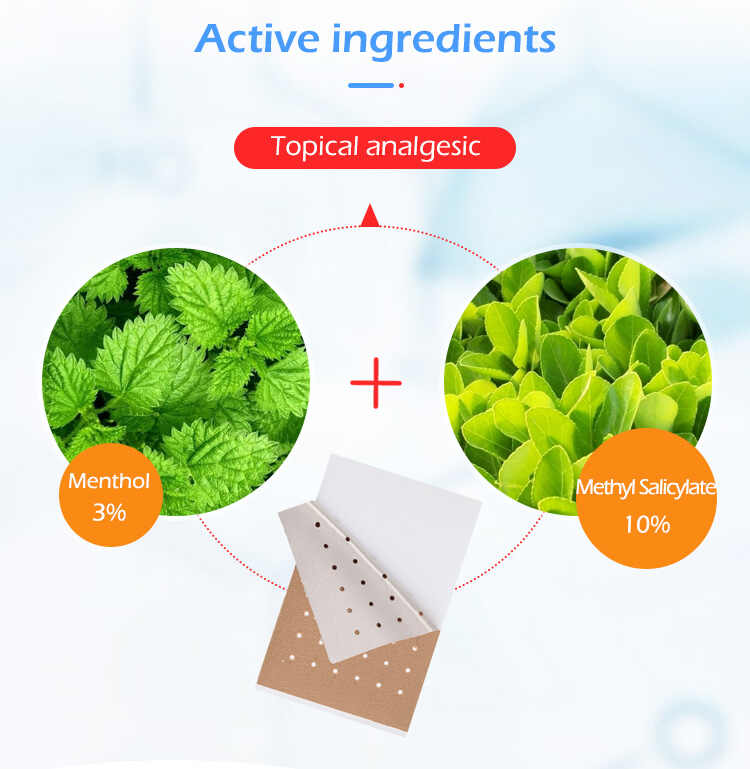

Unique active ingredients (e.g. herbal blends, essential oils)

Innovative delivery mechanisms

Exclusive skin-feel or scent

This positions your brand as innovative, increasing your perceived value — and enabling you to charge premium prices.

B. Targeted Benefits

With Custom Pain Relief Gel Patches, you can address specific market needs:

For athletes: quick absorption and cooling effect

For seniors: gentle adhesive and longer wear time

For women: hormone-friendly or natural ingredients

This enhances product-market fit and brand loyalty.

C. Regulatory and Market Control

OEM partnerships with compliant Pain Relief Gel Patches Manufacturers give you control over:

Ingredient transparency

Certification (FDA, CE, ISO)

Compliance with market-specific claims

You avoid the generic "me-too" products that saturate online marketplaces.

4. When Does Custom Make More Financial Sense?

Custom pain relief patches are a smart investment when:

You plan to scale or distribute internationally

You're entering a premium market

You want control over ingredients and branding

You need exclusive features to avoid price wars

A reliable Pain Relief Gel Patches OEM partner will help you optimize R&D costs and scale production to reach price efficiency over time.

5. How to Reduce the Cost of Custom Pain Relief Gel Patches

1. Choose the Right OEM Manufacturer

A capable Pain Relief Gel Patches Manufacturer can:

Offer in-house R&D to lower development costs

Use cost-effective but high-quality materials

Minimize waste and optimize batch size

Offer discounts on larger volumes

2. Start With a Hybrid Model

Work with a Pain Relief Gel Patches Supplier that offers:

Private label for initial launch

Gradual transition to custom once sales grow

This reduces initial risk while laying the foundation for a premium line.

3. Negotiate Strategic Partnerships

Long-term contracts or volume agreements can:

Reduce unit pricing

Secure better ingredient sourcing deals

Prioritize your brand during peak production seasons

6. Case Study: Comparing Two Brands

| Brand | Option | Outcome |

|---|---|---|

| Brand A | Private Label | Fast market entry, but faces competition on price and differentiation |

| Brand B | Custom Pain Relief Gel Patches OEM | Slower launch, higher costs, but achieves 45% higher profit margin due to brand exclusivity and strong positioning |

7. Summary: Are Custom Pain Relief Gel Patches Worth It?

Yes — if your goal is long-term brand strength, customer loyalty, and profitability.

Although custom patches are more expensive upfront, the added value in performance, marketing appeal, and brand recognition often outweighs the cost.

Meanwhile, Private Label Pain Relief Gel Patches are a good short-term strategy for budget-conscious or first-time entrants.

The best strategy may be a phased approach: start small with private label, then evolve into Custom Pain Relief Gel Patches through a trusted Pain Relief Gel Patches OEM partner.

Related Questions and Answers

Q1: How much more expensive are Custom Pain Relief Gel Patches compared to standard ones?

A: Custom patches can be 20–50% more expensive initially due to R&D and testing. However, with larger production volumes, unit costs can become similar.

Q2: Can I customize only the packaging but keep the standard formulation?

A: Yes. That would fall under Private Label Pain Relief Gel Patches, allowing faster and cheaper entry.

Q3: Are custom patches better in quality?

A: Typically, yes — especially if you choose premium materials or therapeutic actives through a high-quality Pain Relief Gel Patches Manufacturer.

Q4: What is the typical MOQ for Custom Pain Relief Gel Patches?

A: MOQs usually start at 10,000 patches, but some Pain Relief Gel Patches Suppliers offer flexible options.

Q5: Are there hidden costs with custom gel patches?

A: Potential hidden costs include clinical testing, mold/tooling setup, regulatory consulting, and sample iterations. Always clarify with your OEM partner.