A Must-Read for B2B Clients: Inside the Production Process of Sports Pain Patches OEM

In the B2B health and wellness industry, understanding the production process behind a product is vital—especially when it comes to outsourcing through a Sports Pain Patches OEM. For buyers, brand managers, or distributors, having a detailed overview of how Custom Sports Pain Patches are made can help you make informed decisions, manage risk, ensure quality, and maximize profit margins.

This article provides a comprehensive look inside the OEM production process for Sports Pain Patches, from formulation and raw material sourcing to packaging and shipment. Whether you’re a startup planning to launch Private Label Sports Pain Patches, or a seasoned distributor looking to scale, knowing what happens behind the scenes gives you a competitive edge.

1. Understanding Sports Pain Patches OEM Manufacturing

A Sports Pain Patches OEM (Original Equipment Manufacturer) produces pain relief patches that are later branded and sold by B2B clients under their own labels. This model offers flexibility, cost efficiency, and speed-to-market, especially when working with an experienced Sports Pain Patches Manufacturer.

By choosing OEM, B2B clients gain access to:

Proven formulations

High-quality raw materials

Regulatory compliance

Scalable manufacturing infrastructure

Expertise in patch technology

With customization options available, brands can develop Custom Sports Pain Patches that meet their precise needs—functionally and aesthetically.

2. Step-by-Step Breakdown of the OEM Production Process

Let’s walk through the typical production process of Sports Pain Patches OEM, from concept to final delivery.

Step 1: Client Consultation and Requirement Gathering

The first step involves in-depth consultations between the Sports Pain Patches Supplier and the B2B client. Key points discussed include:

Target market (e.g., athletes, elderly, gym-goers)

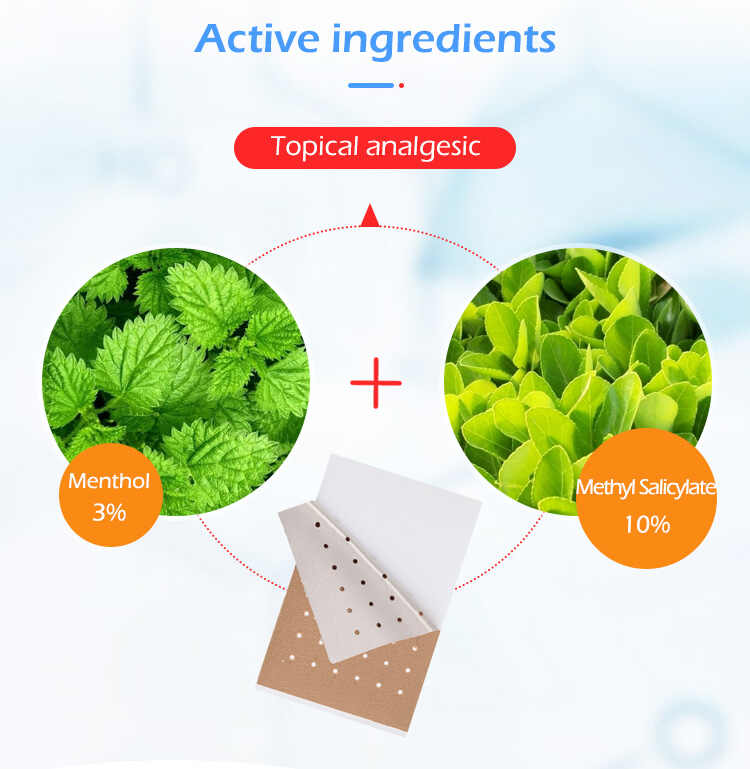

Desired active ingredients (e.g., menthol, capsaicin, CBD, herbal blends)

Patch size, shape, and adhesion strength

Packaging and private label design

Certifications needed (FDA, CE, ISO, GMP, etc.)

This stage ensures that the Custom Sports Pain Patches will be uniquely tailored to your brand and audience.

Step 2: R&D and Formula Development

Once requirements are clear, the Sports Pain Patches Manufacturer begins developing the product formula. A professional R&D team will:

Select the right active and supportive ingredients

Optimize dosage for safety and effectiveness

Conduct stability tests

Evaluate skin absorption and user comfort

Review regional regulations for compliance

You may receive samples for testing during this stage to ensure the patch meets your expectations.

Step 3: Raw Material Sourcing and Quality Control

A high-quality Sports Pain Patches OEM sources medical-grade materials from verified suppliers. Ingredients are tested for:

Purity and potency

Microbial contamination

Heavy metal content

Compliance with pharmaceutical-grade standards

Adhesive materials, backing layers, and release liners are also scrutinized for safety and durability. This guarantees the Custom Sports Pain Patches will be safe, effective, and long-lasting.

Step 4: Patch Manufacturing and Assembly

Manufacturing is conducted in cleanroom environments that comply with GMP standards. The typical process includes:

Mixing: Active ingredients are blended into a gel, hydrogel, or non-woven fabric base.

Coating: The formula is evenly spread onto the backing material.

Cutting: The patches are die-cut into specified shapes and sizes.

Laminating: Layers are laminated to ensure structural integrity and durability.

Drying (if needed): To stabilize the formulation.

Sealing: Patches are sealed in moisture-proof sachets or pouches.

Each batch undergoes in-process quality control to detect any deviations in size, appearance, or composition.

Step 5: Private Label Design and Custom Packaging

This is where your brand comes to life. A reliable Sports Pain Patches Supplier will support you with:

Logo placement and custom graphics

Instructional inserts or QR code links

Eco-friendly or premium packaging options

Tamper-evident seals and barcoding

With Private Label Sports Pain Patches, everything from the outer box to the patch sachet can be fully customized to reflect your brand.

Step 6: Final Quality Inspection

Before dispatch, every order is subjected to rigorous final inspections:

Patch integrity and adhesion performance

Packaging print quality

Label compliance

Batch tracking and documentation

Many Sports Pain Patches OEM manufacturers will provide Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and Batch Production Records (BPR) to ensure full traceability.

Step 7: Warehousing and Shipment

Once cleared, the order is either:

Shipped directly to your fulfillment center

Stored in OEM-controlled warehouses

Distributed to multiple regional partners

Shipping documentation, import/export declarations, and product registration support may also be offered by your OEM partner.

3. Why B2B Clients Trust Sports Pain Patches OEM Solutions

a. Cost-Efficiency

OEM manufacturing eliminates the need for in-house production infrastructure, reducing fixed costs.

b. Speed-to-Market

With pre-developed technologies and scalable production lines, a Sports Pain Patches Manufacturer can fulfill orders quickly.

c. Quality Assurance

Established Sports Pain Patches Suppliers follow GMP and ISO standards, ensuring consistency and safety.

d. Flexibility

Whether you need a small batch of Private Label Sports Pain Patches for a product test or a large production run, OEMs can adapt to your volume needs.

e. Innovation Support

Top-tier OEMs invest in R&D, allowing you to stay ahead of trends with novel formulations and patch technologies.

4. Common Mistakes B2B Clients Should Avoid

Even with a skilled Sports Pain Patches OEM, mistakes can cost time and money. Watch out for:

Inadequate product briefings: Be clear and detailed during the planning phase.

Skipping sample approvals: Always test and approve prototypes before full production.

Choosing based on price alone: The cheapest Sports Pain Patches Supplier might compromise on quality.

Ignoring regulations: Ensure your OEM complies with your target market’s health standards.

5. Final Thoughts: Transparency and Collaboration Are Key

Choosing a Sports Pain Patches OEM isn’t just about finding a supplier—it’s about building a partnership. When the production process is transparent, collaborative, and aligned with your business goals, you’ll be better equipped to launch a standout product that satisfies customers and strengthens your brand.

Whether you need Custom Sports Pain Patches for athletic recovery or Private Label Sports Pain Patches for retail shelves, the right OEM can help you bring that vision to life.

Frequently Asked Questions (FAQ)

1. What is the role of a Sports Pain Patches OEM?

A Sports Pain Patches OEM manufactures pain relief patches for other brands, often providing customization and private label options.

2. Can I customize both the ingredients and packaging?

Yes. An experienced Sports Pain Patches Manufacturer offers full customization, including ingredients, scent, size, shape, and branding.

3. How long does the production process take?

Typical lead times range from 4 to 12 weeks, depending on customization complexity and order size.

4. Are Private Label Sports Pain Patches safe for consumers?

Yes, as long as you partner with a certified Sports Pain Patches Supplier that follows GMP, FDA, and CE standards.

5. What’s the minimum order quantity (MOQ)?

MOQs vary by manufacturer but often start at 5,000 to 10,000 units for custom projects.

6. Can OEM partners help with compliance documents?

Yes. Most Sports Pain Patches OEM providers offer support with CoA, MSDS, and regulatory paperwork.

Conclusion

For B2B clients in the sports health segment, understanding the OEM production process is essential to building a reliable, scalable product line. Partnering with the right Sports Pain Patches Manufacturer gives you access to advanced formulation expertise, efficient production, and flexible customization—all while maintaining compliance and quality.

By going behind the scenes with a trusted Sports Pain Patches OEM, you gain more than just a supplier—you gain a strategic ally in your business success.

Would you like a checklist to help evaluate your next OEM partner?