What Certifications Should I Look for in a Pain Relief Gel Patches Manufacturer?

Choosing the right Pain Relief Gel Patches Manufacturer is not just about product quality or cost—it’s also about ensuring regulatory compliance, safety, and credibility. Whether you are creating Custom Pain Relief Gel Patches, launching a Private Label Pain Relief Gel Patches line, or working with a Pain Relief Gel Patches OEM for international distribution, certifications play a critical role in ensuring your brand’s success and trustworthiness in the market.

In this comprehensive guide, we explore the essential certifications you should require from a Pain Relief Gel Patches Supplier. These credentials protect your business from legal risks, enhance consumer trust, and facilitate smooth market entry in different countries.

1. Why Certifications Matter in the Pain Relief Gel Patch Industry

Pain relief patches are transdermal therapeutic systems, meaning they interact directly with the human body. As such, they fall under strict regulatory scrutiny. Without the appropriate certifications, your product may:

Be barred from entering regulated markets

Face consumer trust issues

Incur penalties from health authorities

Fail safety inspections

That’s why working with a properly certified Pain Relief Gel Patches Manufacturer is essential to long-term success and compliance.

2. Key Global Certifications to Look For

a. GMP (Good Manufacturing Practices)

What it is: A system that ensures products are consistently produced and controlled according to quality standards.

Why it matters: A GMP-certified Pain Relief Gel Patches OEM guarantees:

Controlled production environments

Documented procedures

Regular internal audits

Contamination risk mitigation

Required in: U.S., EU, China, Japan, Canada, and more

Ideal for: Both Custom Pain Relief Gel Patches and Private Label Pain Relief Gel Patches

b. ISO 13485: Medical Devices Quality Management Systems

What it is: An international standard specifically for medical device manufacturers.

Why it matters: ISO 13485-certified Pain Relief Gel Patches Suppliers demonstrate:

Rigorous quality control

Documentation of design, development, and manufacturing

Traceability for all batches

Required in: EU, Canada, Australia, parts of Asia

Especially critical for: Brands targeting pharmaceutical-grade or clinical applications

c. FDA Registration (U.S. Food and Drug Administration)

What it is: For products sold in the United States, FDA registration and/or clearance is mandatory for medical devices.

Why it matters:

Ensures compliance with U.S. health and safety regulations

Required for customs clearance and eCommerce listing (Amazon, Walmart)

Boosts consumer confidence

Applicable for: Pain patches labeled as OTC drugs, Class I or II medical devices

Check for: Whether the Pain Relief Gel Patches Manufacturer has a valid FDA Establishment ID and Device Listing Number.

d. CE Marking (Conformité Européenne)

What it is: Indicates conformity with health, safety, and environmental protection standards for products sold in the European Economic Area (EEA).

Why it matters:

Mandatory for European market entry

Requires product testing, documentation, and a technical file

Applies to products classified as medical devices

Look for: OEMs with experience in submitting CE documentation for Private Label Pain Relief Gel Patches

e. MSDS (Material Safety Data Sheet)

What it is: A document that provides information on the properties of each chemical used in the product.

Why it matters:

Important for customs, storage, and distribution safety

Helps retailers understand how to handle the product

Required for product registration in many countries

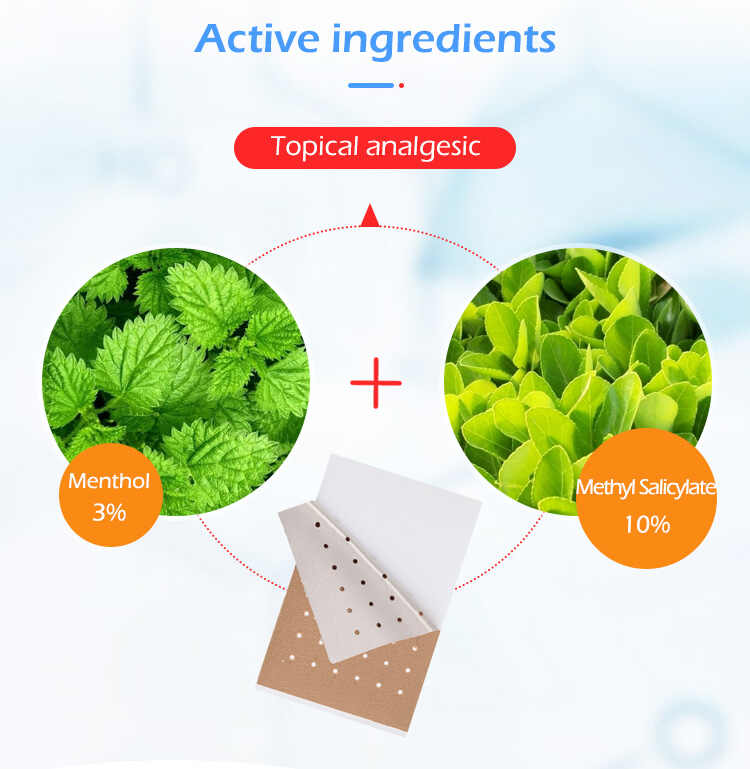

Especially important for: Custom Pain Relief Gel Patches with active ingredients like menthol, camphor, or CBD

f. COA (Certificate of Analysis)

What it is: A document that certifies a product batch meets pre-specified quality standards.

Why it matters:

Confirms product consistency

Used for internal quality assurance and audits

Required when applying for additional certifications or clinical trials

Provided by: Responsible Pain Relief Gel Patches Supplier for each batch produced

g. Dermatological Testing Reports

What it is: Clinical or lab-based evaluations confirming skin safety.

Why it matters:

Boosts product credibility and appeal

Ensures patches don’t cause irritation, burns, or allergic reactions

Especially important for sensitive skin products

Should be requested for: All Private Label Pain Relief Gel Patches targeting sensitive groups like elderly, pregnant women, or children

h. Halal / Vegan / Organic Certifications (If Applicable)

What they are: Voluntary certifications that cater to specific consumer segments.

Why they matter:

Provide additional selling points in niche markets

Required for distribution in specific regions (e.g., Halal for Middle Eastern countries)

Ideal for: Brands emphasizing natural or ethical product positioning

3. How to Verify a Pain Relief Gel Patches Manufacturer’s Certifications

Before signing any contract, verify that your potential Pain Relief Gel Patches OEM partner can provide:

Official documentation with valid dates

Certifications from recognized bodies (SGS, TUV, Intertek, etc.)

Proof of registration on government regulatory sites (e.g., FDA database)

References from past clients who have launched certified products

You may also request a third-party factory audit or virtual inspection.

4. Benefits of Choosing a Fully Certified Manufacturer

Partnering with a fully certified Pain Relief Gel Patches Manufacturer offers:

Market Access: Enables easy entry into U.S., EU, Asia-Pacific, and Middle East markets

Brand Credibility: Certifications are proof points for quality-conscious consumers

Investor Confidence: Certified products are more attractive to investors and distributors

Long-Term Stability: Certified facilities follow consistent, repeatable processes

This is especially important when launching Custom Pain Relief Gel Patches that you want to scale globally.

5. Questions to Ask Your Potential Supplier

Before finalizing your contract with a Pain Relief Gel Patches Supplier, ask:

Do you hold ISO 13485 and GMP certifications?

Are you FDA registered and can you provide your establishment number?

Can you assist with CE marking for the EU?

Will you provide MSDS, COA, and batch testing results?

Do you have dermatological testing reports for sensitive skin?

Are your ingredients certified organic, Halal, or vegan (if relevant)?

Can I inspect or audit your manufacturing facility (physically or virtually)?

These questions help ensure transparency and reduce risks before production begins.

Conclusion

When entering the market with Pain Relief Gel Patches, whether through Private Label, OEM, or Custom formulations, certifications aren’t optional—they are essential. A certified Pain Relief Gel Patches Manufacturer ensures your products meet global regulatory standards, maintain consistent quality, and earn the trust of retailers and end users alike.

By carefully verifying that your chosen Pain Relief Gel Patches OEM or Supplier holds the necessary certifications, you lay a strong foundation for your brand’s reputation and scalability. In a market where safety and trust matter, certified manufacturing is not just a requirement—it's a competitive advantage.

Related Questions and Answers

Q1: Can I sell Pain Relief Gel Patches in the U.S. without FDA certification?

A1: No. FDA registration or clearance is generally required if your patch is classified as a drug or medical device.

Q2: What’s the difference between GMP and ISO 13485?

A2: GMP ensures general manufacturing quality; ISO 13485 is specific to medical devices and includes design and traceability standards.

Q3: Do Private Label Pain Relief Gel Patches need their own certifications?

A3: Not always. You can rely on the manufacturer’s certifications, but you must ensure proper labeling and legal compliance.

Q4: How often are GMP and ISO audits conducted?

A4: Typically once per year. Non-compliance may lead to suspension or revocation of the certification.

Q5: Can a small brand work with a certified Pain Relief Gel Patches Manufacturer?

A5: Yes. Many certified OEMs offer flexible MOQs and startup packages for emerging brands.