What Certifications Should an Effective Pain Relief Patches Manufacturer Have?

In the competitive and highly regulated healthcare industry, certifications are more than just documents—they’re proof of trust, safety, and quality. If you're considering entering the market with Private Label Effective Pain Relief Patches, working with a certified Effective Pain Relief Patches Manufacturer is non-negotiable. Certifications serve as the foundation for compliance, consumer trust, and product success.

In this article, we will explore the essential certifications every Effective Pain Relief Patches OEM should have, why these certifications matter, and how they influence the development of Custom Effective Pain Relief Patches. Whether you're an entrepreneur, distributor, or a growing brand looking for a reliable Effective Pain Relief Patches Supplier, this guide will help you make informed decisions that protect your brand and your customers.

Why Certifications Matter in Effective Pain Relief Patch Manufacturing

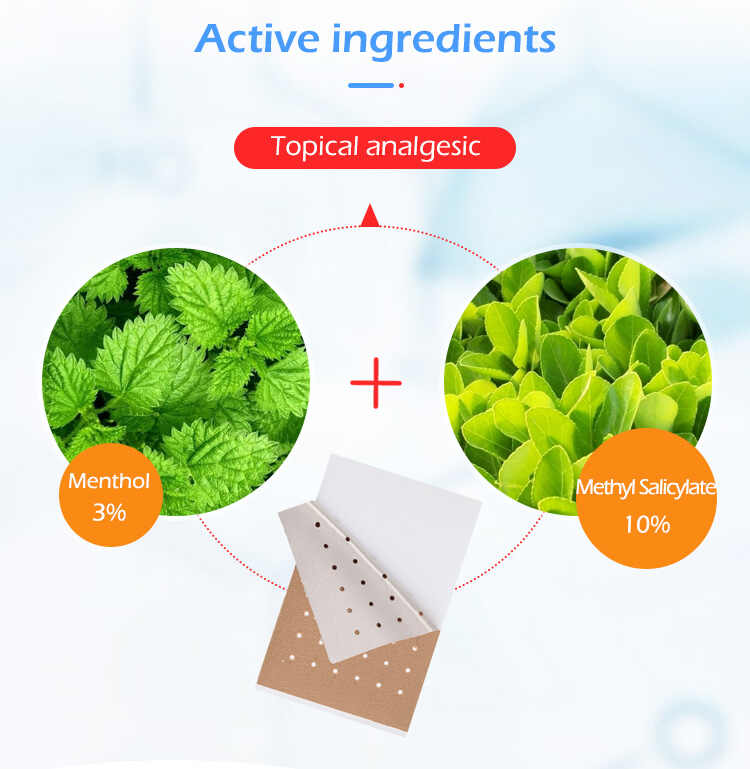

Pain relief patches, especially transdermal ones, interact directly with the body’s largest organ—the skin. Because they deliver active ingredients directly into the bloodstream or muscle tissue, ensuring product safety, efficacy, and quality is critical. That’s where certifications come in.

Partnering with a certified Effective Pain Relief Patches Manufacturer means:

Regulatory compliance in domestic and international markets

Higher product quality and consistency

Reduced risk of product recalls or customer complaints

Stronger brand reputation and consumer trust

Easier access to retail and distribution channels

Let’s now explore the most important certifications your manufacturer should hold.

1. GMP (Good Manufacturing Practice) Certification

Why it matters: GMP is the most fundamental certification for any Effective Pain Relief Patches OEM. It ensures that products are manufactured under strict hygiene, process control, and documentation standards.

Key Benefits:

Assures product quality and batch-to-batch consistency

Covers the entire production chain—from raw materials to final packaging

Prevents contamination, errors, and risks to consumers

Required by regulatory bodies like the FDA, EMA, and WHO

What to look for:

GMP certificates issued by a recognized authority (e.g., FDA, WHO, SGS)

Clear documentation and traceability of ingredients and processes

Regular third-party audits of the manufacturing facility

If your Effective Pain Relief Patches Supplier isn’t GMP-certified, that’s a red flag.

2. ISO 13485 Certification (Medical Devices Quality Management System)

Why it matters: ISO 13485 is a global standard specific to the manufacture of medical devices—including Custom Effective Pain Relief Patches considered medical-grade. It ensures a higher level of safety, risk management, and compliance.

Key Benefits:

Aligns manufacturing with international medical device standards

Improves internal processes and minimizes errors

Required for CE-marking and other international certifications

This certification is especially important if you plan to sell your Private Label Effective Pain Relief Patches in markets like Europe, Canada, or Australia.

3. FDA Registration (U.S. Food and Drug Administration)

Why it matters: The U.S. is one of the largest consumer markets for pain relief products. To legally sell Private Label Effective Pain Relief Patches in the United States, the manufacturing facility must be registered with the FDA.

FDA Oversight May Include:

OTC Drug Monograph compliance for active ingredients like menthol or camphor

Facility inspection and GMP adherence

Product listing under NDC (National Drug Code)

While FDA approval is typically reserved for prescription products, FDA registration and compliance with the OTC monograph are mandatory for most over-the-counter Effective Pain Relief Patches.

4. CE Certification (for European Markets)

Why it matters: If your business model includes exporting Custom Effective Pain Relief Patches to the EU, CE certification is a must. It indicates that the product complies with EU health, safety, and environmental protection standards.

CE Covers:

Safety and efficacy of transdermal and topical patches

Labeling, instructions, and packaging compliance

Risk assessments and clinical evaluations

A trusted Effective Pain Relief Patches OEM should be well-versed in CE-marking procedures, especially for Class I or Class IIa medical devices.

5. MSDS (Material Safety Data Sheet) and COA (Certificate of Analysis)

Why they matter: These documents are not standalone certifications but are essential for transparency and product safety validation.

MSDS provides detailed information about each ingredient’s chemical composition, hazards, handling, and first-aid measures.

COA certifies that a batch of Private Label Effective Pain Relief Patches meets predetermined quality and safety criteria.

Your Effective Pain Relief Patches Supplier should provide both documents for every batch, especially if you’re offering Custom Effective Pain Relief Patches with unique ingredients.

6. ISO 9001 Certification (Quality Management Systems)

Why it matters: ISO 9001 is a general quality management certification that shows the manufacturer is committed to continual improvement, customer satisfaction, and process efficiency.

Key Benefits:

Enhances operational performance

Reduces the likelihood of defects or recalls

Increases reliability of delivery and service

Required by many global retail chains

For companies aiming to scale, ISO 9001 compliance from your Effective Pain Relief Patches Manufacturer ensures they can support you consistently as your business grows.

7. HALAL, Vegan, and Cruelty-Free Certifications (Optional but Advantageous)

In today’s conscious consumer landscape, offering Private Label Effective Pain Relief Patches that cater to specific values can be a market differentiator.

Look for certifications like:

HALAL: For Middle Eastern and Muslim-majority markets

Vegan: Assurance that no animal-derived ingredients are used

Cruelty-Free: No animal testing at any stage of product development

If your brand targets niche wellness markets or values-based consumers, choosing a flexible Effective Pain Relief Patches OEM that offers such options adds value.

8. Environmental Certifications (e.g., ISO 14001)

Sustainability is no longer a trend—it’s an expectation. Certifications like ISO 14001 demonstrate that your Effective Pain Relief Patches Manufacturer minimizes environmental impact through responsible production practices.

Benefits include:

Better brand perception

Lower carbon footprint

Easier compliance with sustainability-focused retailers

This is especially relevant when creating eco-friendly Custom Effective Pain Relief Patches for health-conscious and environmentally aware consumers.

How to Verify a Manufacturer’s Certifications

Before partnering with any Effective Pain Relief Patches Supplier, verify the legitimacy of their certifications. Here’s how:

Request physical or digital copies of certificates

Check expiration dates and renewal history

Verify issuing bodies (e.g., SGS, NSF, FDA)

Ask for audit reports or third-party inspection records

Visit the manufacturing site if possible

A reputable Effective Pain Relief Patches OEM will be transparent and proactive in sharing this information.

Conclusion: Certifications Build the Foundation for Long-Term Success

In the health and wellness industry, your brand is only as credible as the manufacturer behind it. By choosing a certified Effective Pain Relief Patches Manufacturer, you’re not just ensuring compliance—you’re building trust, quality assurance, and long-term customer satisfaction.

Whether you're developing Custom Effective Pain Relief Patches or launching a full line of Private Label Effective Pain Relief Patches, the certifications your manufacturing partner holds will directly impact your product’s safety, scalability, and profitability.

Don’t compromise. Choose an Effective Pain Relief Patches Supplier with proven compliance, a track record of excellence, and the credentials to back it up.

Related Questions & Answers

1. Why are GMP certifications important for Effective Pain Relief Patches Manufacturers?

GMP ensures that products are consistently produced and controlled according to quality standards. It’s essential for safety, efficacy, and regulatory compliance.

2. Is FDA approval required for Private Label Effective Pain Relief Patches?

For OTC products, FDA approval is not typically required, but FDA registration and compliance with the OTC drug monograph are mandatory.

3. Can I sell pain relief patches in Europe without CE certification?

No. CE certification is legally required to sell transdermal patches as medical devices in the EU.

4. What’s the difference between ISO 9001 and ISO 13485?

ISO 9001 focuses on general quality management across industries, while ISO 13485 is specific to medical devices, making it more applicable to Effective Pain Relief Patches OEMs.

5. What documents should I ask from an Effective Pain Relief Patches Supplier?

Request GMP certificates, ISO certifications, FDA registration, MSDS, COA, and any market-specific approvals like CE or HALAL.

6. Are Vegan or Cruelty-Free certifications important for pain relief patches?

Yes, especially if you target conscious consumers. These certifications can differentiate your Custom Effective Pain Relief Patches and increase market appeal.