The Process of OEM Herbal Pain Patch Production for B2B Clients

In today’s competitive health and wellness market, businesses are increasingly seeking to offer unique, natural solutions to meet their customers' needs. One such solution is herbal pain patches, which provide targeted, natural pain relief through topically applied, plant-based ingredients. For B2B clients, the ability to customize and private label these patches through Herbal Pain Patches OEM (Original Equipment Manufacturing) partnerships presents an excellent opportunity to create exclusive, branded products.

The process of OEM herbal pain patch production involves several stages, from formulation and ingredient sourcing to manufacturing, quality control, and packaging. In this comprehensive guide, we will discuss the steps involved in producing custom herbal pain patches for B2B clients, the benefits of working with an experienced Herbal Pain Patches Supplier, and how businesses can ensure a successful partnership with an Herbal Pain Patches Manufacturer.

1. Initial Consultation and Product Customization

The first step in the OEM herbal pain patch production process is the initial consultation with a trusted Herbal Pain Patches Supplier or Herbal Pain Patches Manufacturer. This is where businesses outline their specific needs, goals, and brand vision for the product. Key factors that are typically discussed during this stage include:

Targeted pain relief: Whether the patches will be used for muscle pain, joint pain, inflammation, or other conditions, businesses need to specify the type of pain they want to target.

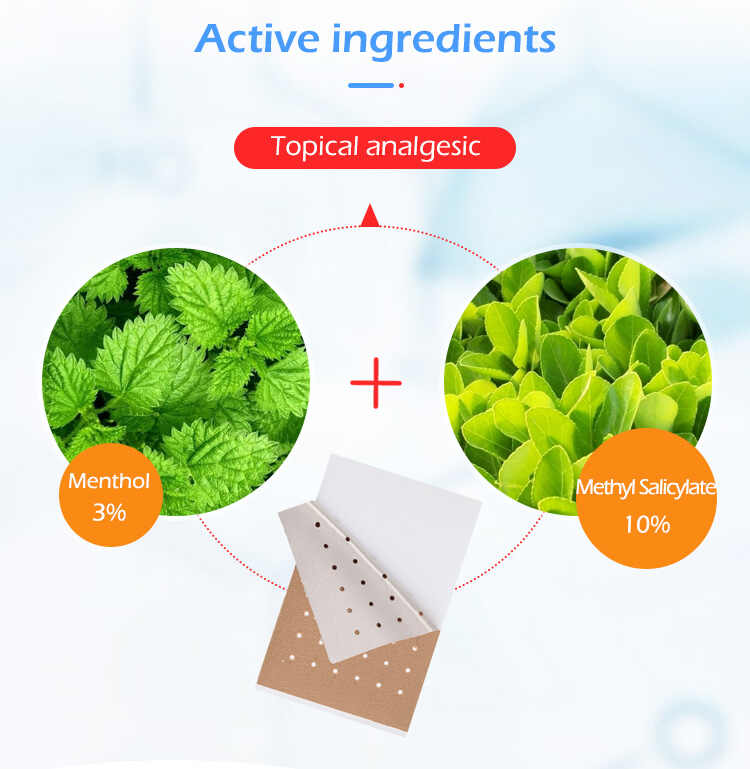

Ingredient preferences: Companies may want to incorporate certain herbal ingredients like menthol, camphor, eucalyptus, or even more niche herbs like turmeric or arnica.

Formulation strength: Depending on the intended use, businesses can customize the strength of the formulation to offer mild to strong pain relief.

Patch size and design: The physical design of the patch is an important consideration, as it should be comfortable, discreet, and effective for the intended customer.

Sustainability: Eco-friendly materials, such as biodegradable or recyclable packaging, may be requested if the company aims to position the product as environmentally conscious.

Once these specifications are agreed upon, the Herbal Pain Patches OEM manufacturer can begin developing the product prototype.

2. Ingredient Sourcing and Testing

After the product is conceptualized, the next step is sourcing the ingredients and conducting thorough testing. The quality of the ingredients used in custom herbal pain patches directly impacts the effectiveness of the product. Reliable Herbal Pain Patches Suppliers work closely with their clients to ensure that only the highest quality, natural ingredients are used in the formulation.

Testing during this phase typically includes:

Sourcing raw materials: Ethical sourcing is crucial for businesses that want to align their products with consumer values such as sustainability and transparency. Ingredients should be sourced from reputable suppliers to ensure purity and quality.

Laboratory testing: The herbal ingredients undergo lab tests to ensure they are potent, safe, and free from contaminants. This process also includes testing for potential allergens.

Stability testing: To ensure the ingredients remain effective over time, stability tests are conducted to evaluate how the herbal pain patch reacts to different environmental conditions, including temperature and humidity.

Through rigorous testing, businesses can be confident that their private label herbal pain patches will meet both regulatory standards and consumer expectations.

3. Prototyping and Formulation Refinement

Once the ingredients are sourced and tested, the manufacturer begins creating a prototype of the herbal pain patch. This prototype is essential for evaluating the product's functionality, comfort, and overall design. During the prototyping phase, the following key factors are assessed:

Adhesive performance: The patch must stay securely in place once applied to the skin, providing long-lasting relief without irritation.

Skin compatibility: Since herbal pain patches are applied directly to the skin, the adhesive and herbal ingredients must be gentle and non-irritating.

Herbal infusion effectiveness: The active ingredients should be infused in the right proportions to provide optimal pain relief without compromising the patch's integrity.

Once the prototype is ready, businesses can evaluate its performance and suggest any necessary changes or adjustments. This step allows for fine-tuning the product before mass production begins.

4. Manufacturing Process

Once the product has been finalized and the prototype is approved, manufacturing begins. The Herbal Pain Patches OEM manufacturer is responsible for overseeing the production process, ensuring that all steps meet quality standards. The typical steps in the manufacturing of herbal pain patches include:

Batch production: The raw ingredients are mixed in precise proportions to create a consistent formulation for each batch of patches.

Herbal infusion: The herbal ingredients are infused into the patches using specialized techniques to ensure they are evenly distributed and effective when applied to the skin.

Adhesive application: The adhesive layer is applied to the back of the patch, ensuring it will adhere securely to the skin without causing discomfort.

Cutting and shaping: The patches are cut into the desired size and shape, ensuring uniformity and ease of application.

During this phase, the Herbal Pain Patches Manufacturer ensures that the entire production process adheres to high standards of hygiene, quality control, and efficiency.

5. Quality Control and Testing

Quality control is a critical component of the OEM herbal pain patch production process. To ensure that each batch of custom herbal pain patches is safe, effective, and consistent, rigorous testing is conducted at various stages of production. These tests include:

Visual inspection: The patches are inspected for any defects, such as irregular shapes or faulty adhesive application.

Performance testing: Each patch is tested for its adhesion strength, ensuring that it stays in place during use.

Ingredient potency: Random samples are tested to confirm that the herbal ingredients are effective and present in the correct proportions.

Skin irritation tests: Patches are tested on a small group of volunteers to ensure they do not cause skin irritation or allergic reactions.

A reliable Herbal Pain Patches Supplier will have strict quality control measures in place, ensuring that every batch of patches meets the required standards.

6. Packaging and Branding

Once the custom herbal pain patches pass all quality control tests, they move on to packaging. For B2B clients who are offering private label herbal pain patches, this stage is crucial for branding and differentiation. The packaging design is an opportunity to showcase your brand's identity and message.

Key factors to consider when designing packaging for herbal pain patches include:

Branding: The packaging should reflect your brand’s image, including your logo, color scheme, and overall aesthetic.

Instructions: Clear instructions on how to apply the patch, as well as information about the active ingredients, should be included.

Sustainability: If sustainability is important to your brand, ensure the packaging is made from recyclable or eco-friendly materials.

Compliance: Packaging must include all necessary regulatory information, such as ingredient lists, safety warnings, and manufacturer details.

The right packaging not only enhances your brand’s visibility but also helps build consumer trust and satisfaction.

7. Shipping and Distribution

The final step in the OEM herbal pain patch production process is shipping and distribution. Once the patches are packaged, they are ready for delivery to the B2B client. Depending on the terms of the partnership, the Herbal Pain Patches Manufacturer may handle the logistics, or the client may take responsibility for distribution.

During this phase, businesses should work with their Herbal Pain Patches Supplier to ensure timely delivery and that the products arrive in perfect condition. Efficient distribution helps businesses maintain a steady supply of custom herbal pain patches, ensuring they can meet demand without interruption.

Conclusion

The OEM herbal pain patch production process is a detailed, multi-step journey that requires collaboration between the B2B client and a skilled Herbal Pain Patches Manufacturer or Herbal Pain Patches OEM supplier. From initial consultation to final delivery, customization ensures that businesses can offer high-quality, branded herbal pain relief products that meet the needs of their target market.

By understanding and engaging in each stage of the process, businesses can create custom herbal pain patches that align with their brand values, target customer needs, and industry trends, ensuring a competitive edge in the marketplace.

Related Questions and Answers:

1. What is the first step in customizing herbal pain patches for my brand?

The first step is the initial consultation with a reliable Herbal Pain Patches Supplier or Herbal Pain Patches Manufacturer, where you can outline your product needs, including ingredients, target pain relief, and design preferences.

2. How do I ensure the quality of my custom herbal pain patches?

Quality control is crucial. Work with a supplier who conducts rigorous testing at every stage, from raw ingredient sourcing to final product inspection, ensuring consistency and effectiveness.

3. What should I consider when designing the packaging for my private label herbal pain patches?

Your packaging should reflect your brand identity, include clear instructions, and comply with regulatory standards. Consider using sustainable materials to appeal to eco-conscious consumers.

4. How long does the production process take for herbal pain patches?

The production timeline varies depending on the complexity of customization, but it typically involves a few weeks for prototyping, testing, and manufacturing before the final product is ready for distribution.

5. Can I order small batches of herbal pain patches for my business?

Yes, many Herbal Pain Patches Manufacturers offer flexibility in batch sizes, allowing businesses to order small batches for initial testing or limited runs before scaling up production.