Core Technologies and Processes in Chronic Pain Patches OEM Customization

As demand for non-invasive, long-lasting pain relief solutions rises globally, Chronic Pain Patches have emerged as a game-changer in the pharmaceutical and wellness industries. For brands entering this space, working with a Chronic Pain Patches OEM is a smart way to streamline production, leverage innovation, and maintain compliance with health regulations. However, what truly sets one Chronic Pain Patches Manufacturer apart from another is the depth of their core technologies and the precision of their customization processes.

In this comprehensive guide, we explore the cutting-edge technologies and customization processes that high-quality Chronic Pain Patches Suppliers utilize to deliver effective, compliant, and market-ready Custom Chronic Pain Patches and Private Label Chronic Pain Patches.

1. Introduction to OEM Customization for Chronic Pain Patches

OEM (Original Equipment Manufacturer) customization refers to the process of tailoring a product’s formulation, structure, and packaging based on a client’s brand, target market, and regulatory requirements. In the case of Chronic Pain Patches, OEMs not only manufacture the products but also support:

Ingredient selection

Patch delivery system engineering

Design and packaging

Compliance documentation

Private labeling

A reliable Chronic Pain Patches OEM offers both flexibility and innovation through proprietary technologies, proven production methods, and strict quality assurance protocols.

2. Key Technologies in Chronic Pain Patches OEM Manufacturing

a. Transdermal Drug Delivery Systems (TDDS)

The heart of any Chronic Pain Patch is its ability to deliver active ingredients through the skin and into the bloodstream or local tissue. TDDS technology enables:

Controlled release of medication over 8–72 hours

Non-invasive pain management

Bypassing of the gastrointestinal tract, reducing systemic side effects

There are multiple TDDS systems used by leading Chronic Pain Patches Manufacturers, including:

Matrix-type patches: Drug is embedded in the adhesive layer

Reservoir-type patches: Drug is stored in a separate layer and delivered via a membrane

Multilaminate systems: Combine both for extended control and efficiency

b. Micro-Encapsulation and Nanotechnology

Advanced Chronic Pain Patches OEM partners incorporate micro-encapsulation to:

Improve ingredient stability

Enable sustained release of medication

Minimize skin irritation

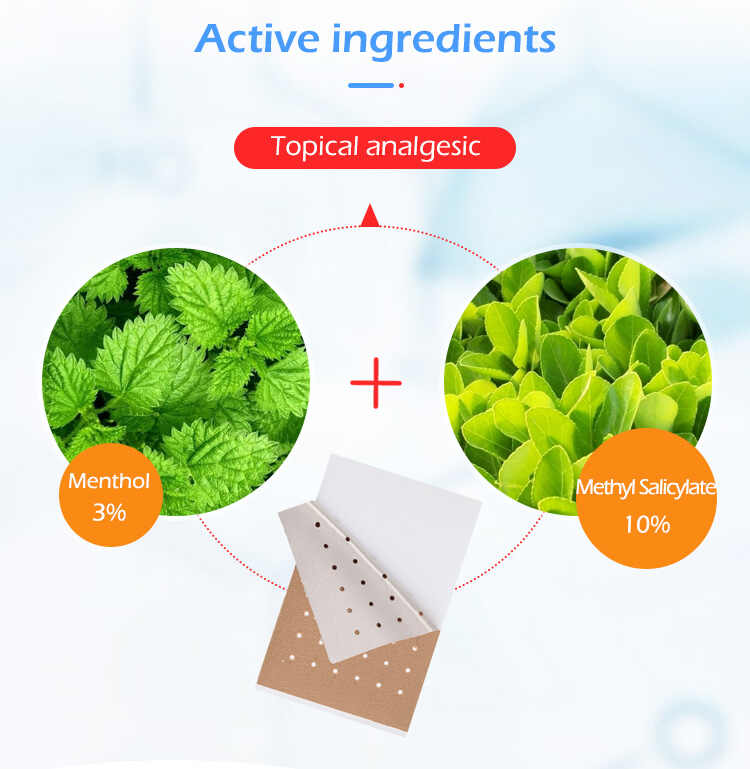

Some also use nanotechnology to enhance skin penetration for active compounds like menthol, lidocaine, CBD, and capsaicin.

c. Adhesive Technology

Adhesion plays a critical role in user experience. Top Chronic Pain Patches Suppliers use adhesives that are:

Skin-safe and hypoallergenic

Water-resistant or breathable, depending on application

Flexible for joint areas

Sophisticated adhesive systems ensure that the patch stays in place while maintaining user comfort.

d. Herbal Integration and Botanical Technology

For Custom Chronic Pain Patches, many brands now prefer natural formulations. OEMs with botanical expertise can integrate:

Traditional Chinese Medicine (TCM) herbs

Ayurvedic plant extracts

Organic essential oils

An experienced Chronic Pain Patches Manufacturer will be able to process and stabilize these herbs effectively without compromising efficacy.

e. Thermo-Responsive and Hydrogel Technologies

Hydrogels are increasingly used in Private Label Chronic Pain Patches due to their cooling effect, moisture retention, and ease of use. Meanwhile, thermo-responsive polymers adapt to body temperature and release active ingredients more effectively.

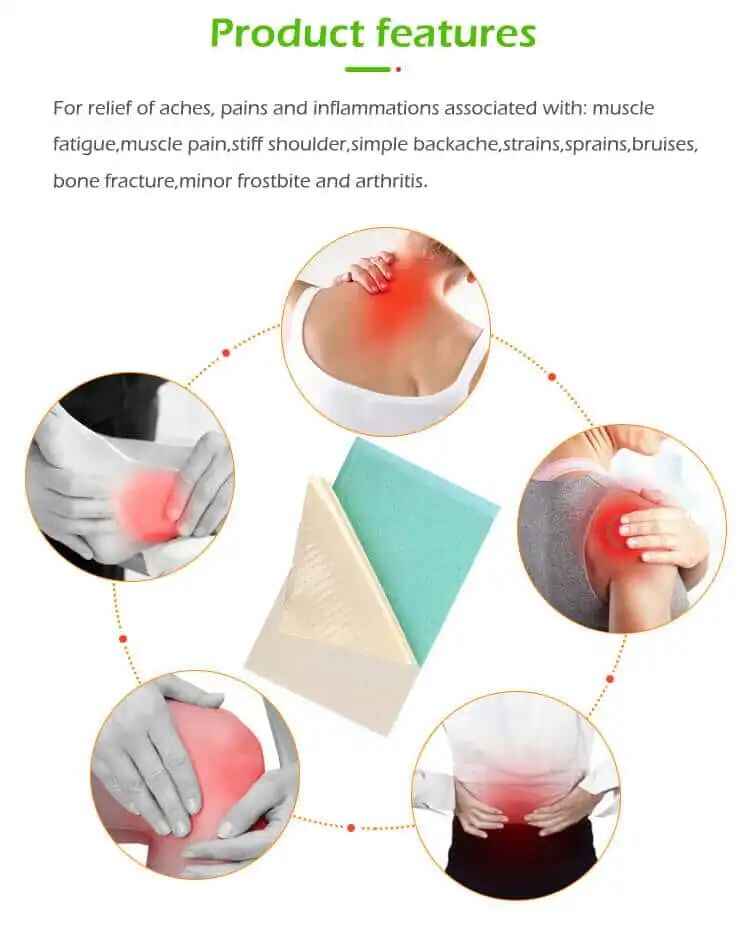

Hydrogel patches are particularly favored for:

Chronic lower back pain

Arthritis and joint pain

Muscle fatigue in athletes

3. The Customization Process in Chronic Pain Patches OEM

The customization of Chronic Pain Patches involves several coordinated steps between the brand owner and the OEM manufacturer:

a. Client Needs Assessment

A qualified Chronic Pain Patches Supplier starts by understanding:

Target audience (e.g., elderly, athletes, office workers)

Desired active ingredients and patch duration

Regulatory region (USA, EU, Middle East, etc.)

Branding and packaging vision

b. Formulation Development

R&D teams at the Chronic Pain Patches Manufacturer formulate blends tailored to:

Specific pain conditions (muscle, joint, neuropathic)

Active ingredient preferences (chemical, herbal, CBD, etc.)

Regulatory safety thresholds

This is the phase where Custom Chronic Pain Patches are truly born.

c. Prototype Creation and Testing

Once a formulation is approved, the OEM creates a prototype for:

Adhesion testing

Wearability trials

Efficacy assessment

Stability and shelf-life testing

Some advanced OEMs also use in vitro skin permeation testing to simulate how well the patch delivers the drug.

d. Regulatory Support and Documentation

High-quality OEMs ensure that Private Label Chronic Pain Patches meet:

FDA or CE regulations

ISO 13485 manufacturing standards

MSDS and COA documentation

Claims and label compliance (e.g., “non-irritating”, “long-lasting relief”)

This is especially crucial for pain patches that contain active pharmaceuticals or herbal remedies subject to local health authority rules.

e. Packaging and Branding

Packaging must balance regulatory requirements with brand aesthetics. A full-service Chronic Pain Patches OEM will help with:

Package engineering (barriers for moisture and UV)

Graphic design and compliance

Multilingual labeling

Eco-conscious packaging materials

OEMs offering Private Label Chronic Pain Patches often provide low MOQ packaging options to support startups.

f. Mass Production and Quality Control

Before scaling up, OEMs typically conduct pilot runs to fine-tune:

Production speed and consistency

Adhesion quality

Ingredient dispersal

Defect rates

Quality control includes:

Visual inspection

Microbiological testing

Active ingredient concentration validation

Adhesion strength analysis

4. Benefits of Working with a High-Tech Chronic Pain Patches OEM

Partnering with a technologically advanced Chronic Pain Patches Manufacturer offers several advantages:

Speed to market: Reduced R&D and production times

Cost efficiency: Shared infrastructure and bulk material sourcing

Regulatory ease: Expert guidance on compliance and documentation

Brand differentiation: Unique Custom Chronic Pain Patches with tailored effects

Scalability: Ability to grow with demand without compromising quality

5. Choosing the Right OEM Partner for Custom Chronic Pain Patches

When selecting a Chronic Pain Patches Supplier, prioritize:

Experience: Years of expertise in pain management patches

Technology stack: Availability of advanced TDDS, hydrogels, microencapsulation

Customization flexibility: Both herbal and chemical options

Regulatory support: For global distribution

Transparency: Willingness to share test data, facility tours, certifications

A truly reliable Chronic Pain Patches OEM is more than a manufacturer—they are a strategic partner in your brand’s long-term success.

Conclusion

The customization of Chronic Pain Patches through a competent OEM involves much more than just slapping a label on a generic product. It requires deep expertise in drug delivery, skin science, formulation chemistry, and packaging compliance. Whether you're building a new brand or expanding an existing one, working with a Chronic Pain Patches Manufacturer who offers advanced technologies and rigorous processes is essential.

Investing in a reliable Chronic Pain Patches OEM not only ensures a high-quality product but also positions your brand as trustworthy, effective, and innovative in a fast-growing health market.

Related Questions and Short Answers

Q1: What makes a Chronic Pain Patches OEM different from a regular manufacturer?

A: An OEM provides custom formulations, regulatory support, and private label options, while regular manufacturers usually offer fixed, off-the-shelf products.

Q2: Can a Chronic Pain Patches Supplier help me create herbal patches?

A: Yes, many advanced suppliers specialize in botanical and natural formulations, especially those with Traditional Chinese Medicine (TCM) or Ayurvedic experience.

Q3: What ingredients are commonly used in Custom Chronic Pain Patches?

A: Common actives include menthol, lidocaine, capsaicin, salicylates, CBD, and various herbal extracts.

Q4: How long does it take to develop a Private Label Chronic Pain Patch?

A: Private label patches may be ready in 4–8 weeks, while custom formulations may require 2–6 months including testing and approvals.

Q5: What is the advantage of hydrogel-based Chronic Pain Patches?

A: Hydrogels are cooling, non-greasy, and offer excellent skin adhesion and moisture retention, enhancing user comfort.

Q6: Do OEMs handle product registration with health authorities?

A: Yes, most high-quality Chronic Pain Patches OEMs assist with regulatory submissions and can provide all required documentation.

Q7: Can I order a small batch of Custom Chronic Pain Patches to test the market?

A: Many OEMs now offer low MOQs for initial product launches or pilot campaigns.