Capsicum Heat Patches OEM: How to Reduce Costs Without Compromising Quality

In the competitive natural pain relief market, partnering with a reliable Capsicum Heat Patches Manufacturer through Capsicum Heat Patches OEM services is essential for businesses looking to deliver effective products while maintaining healthy profit margins. However, cost reduction often becomes a critical challenge, especially when scaling up production or entering new markets. The question many brands ask is: How can you reduce costs without compromising quality when producing Custom Capsicum Heat Patches or Private Label Capsicum Heat Patches?

This detailed guide explores proven strategies for cost optimization during Capsicum Heat Patches OEM production, emphasizing maintaining product integrity, regulatory compliance, and brand reputation.

Understanding the Cost Drivers in Capsicum Heat Patches OEM Production

Before diving into cost-saving measures, it's vital to understand the key factors influencing production costs:

Raw Material Quality and Pricing: Capsaicin extract, herbal blends, adhesive materials, and patch backings.

Manufacturing Processes: Labor, machinery efficiency, and production line setup.

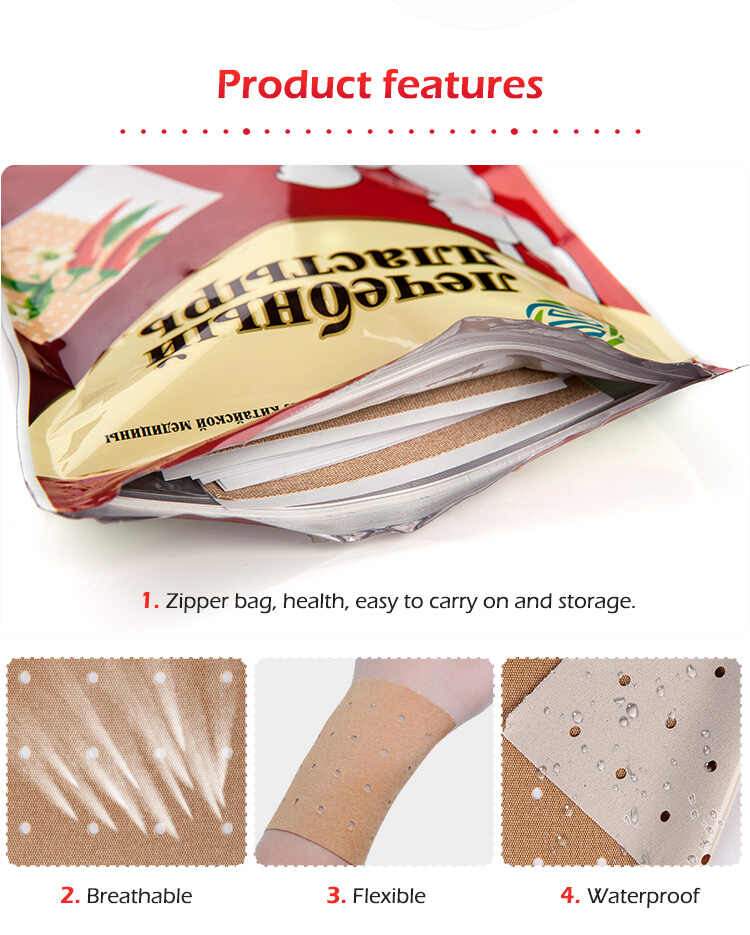

Packaging Design and Materials: Custom boxes, labels, inserts, and compliance printing.

Certification and Testing: Quality control, regulatory approvals, and safety testing.

Order Volume and Supply Chain Management: Minimum order quantities (MOQ), logistics, and inventory management.

Each factor plays a role in the overall cost structure for your Capsicum Heat Patches OEM product.

Strategies to Reduce Costs Without Sacrificing Quality

1. Partner with an Experienced Capsicum Heat Patches Manufacturer

An OEM partner with established expertise can leverage:

Economies of scale in raw material sourcing.

Efficient production techniques reducing waste and downtime.

Proven formulations minimizing costly trial-and-error.

Their industry knowledge ensures you get high-quality Custom Capsicum Heat Patches at optimized prices.

2. Optimize Raw Material Selection

While it’s tempting to cut costs by using lower-quality ingredients, this often backfires by compromising efficacy and safety. Instead:

Source raw materials through your Capsicum Heat Patches Supplier’s vetted network, which typically secures better pricing due to bulk purchasing.

Consider alternative natural herb blends that maintain effectiveness but reduce costs.

Evaluate suppliers regularly for pricing competitiveness without sacrificing quality standards.

3. Balance Customization and Cost

Custom features add value but can also increase costs. To balance:

Limit customization to high-impact areas like packaging design or capsaicin concentration rather than extensive formulation changes.

Use standardized patch sizes and adhesives where possible to lower tooling and material costs.

Opt for Private Label Capsicum Heat Patches if your budget limits full customization; these use proven formulas with your branding.

4. Negotiate MOQ and Production Runs

MOQ affects unit cost significantly. Strategies include:

Negotiate flexible MOQs with your Capsicum Heat Patches OEM partner, especially for startups testing markets.

Plan production runs to align with sales forecasts to avoid costly overstock or emergency small-batch orders.

Consolidate orders with multiple SKUs to achieve volume discounts.

5. Simplify Packaging Without Losing Brand Appeal

Packaging can be a hidden cost driver. Reduce expenses by:

Using minimalist, eco-friendly packaging that appeals to modern consumers.

Avoiding expensive inserts or multi-layered boxes unless strategically necessary.

Partnering with your Capsicum Heat Patches Manufacturer for integrated packaging services to cut outsourcing costs.

6. Streamline Supply Chain and Logistics

Efficient logistics can reduce costs and improve reliability:

Source your Capsicum Heat Patches from manufacturers near your distribution centers.

Coordinate shipping schedules to maximize container usage.

Use local fulfillment centers to minimize last-mile costs.

7. Invest in Quality Control Early

Poor quality leads to returns, regulatory issues, and brand damage, costing more in the long run. Ensure your OEM partner:

Implements strict quality assurance protocols.

Provides testing and certification support.

Offers product warranties or guarantees.

This approach reduces downstream costs and maintains customer trust.

Benefits of Cost-Effective OEM Partnerships

Improved Profit Margins: Lower production costs mean higher margins or competitive retail pricing.

Scalable Production: Cost control enables you to expand product lines or enter new markets efficiently.

Consistent Quality: Reliable suppliers maintain product standards that support brand reputation.

Faster Time-to-Market: Efficient processes reduce lead times, allowing quicker response to market demands.

Real-World Examples

Brand X reduced costs by 15% by switching to a Capsicum Heat Patches Supplier with local raw material sourcing and flexible MOQs, without any drop in product quality.

Brand Y optimized packaging design through their OEM partner, lowering packaging costs by 20% and attracting eco-conscious customers with minimalist designs.

Final Thoughts: Balancing Cost and Quality in Capsicum Heat Patches OEM

Reducing costs while maintaining product quality is achievable with strategic OEM partnerships. By understanding cost drivers and collaborating closely with a trustworthy Capsicum Heat Patches Manufacturer, you can create high-quality Custom Capsicum Heat Patches and Private Label Capsicum Heat Patches that satisfy consumers and protect your brand.

Related Questions and Answers

1. How can I reduce costs in Capsicum Heat Patches OEM without lowering quality?

Partner with experienced manufacturers, optimize raw material sourcing, balance customization, and streamline packaging and logistics.

2. What is the impact of MOQ on production cost?

Higher MOQs usually reduce the unit cost but require larger upfront investment. Negotiating flexible MOQs can help balance costs.

3. Should I choose custom or private label patches to save costs?

Private label patches are generally less expensive since they use existing formulas, while custom patches offer differentiation but cost more.

4. How important is quality control in cost reduction?

Investing in quality control prevents costly product recalls, returns, and regulatory issues, protecting your brand and reducing long-term costs.

5. Can packaging design affect my overall production costs?

Yes, simplifying packaging and using eco-friendly materials can significantly lower costs while appealing to consumers.

6. How to find a reliable Capsicum Heat Patches Supplier?

Look for certifications, ask for references, verify their manufacturing processes, and request product samples and quality reports.